Comprehensive services

We know from our own experience that being dependent on suppliers can have a negative effect on the quality of services provided and very often on delivery deadlines as well. We avoid this problem by bringing together top experts and top-notch equipment in our company, thereby allowing us to use our own workforce to manage the entire process, from machine design, programming, MAR, electrical installation and the mechanical production of atypical parts to the assembly of prototypes and testing. This lets TEMEX offer its customers comprehensive services, from analysis at the start to professional maintenance and care at the end.

Design

The development of an automated workplace begins in our design department, which is equipped with the latest computer technology, including advanced 3D software technologies for design and testing. The electrical design division is also involved in machine design.

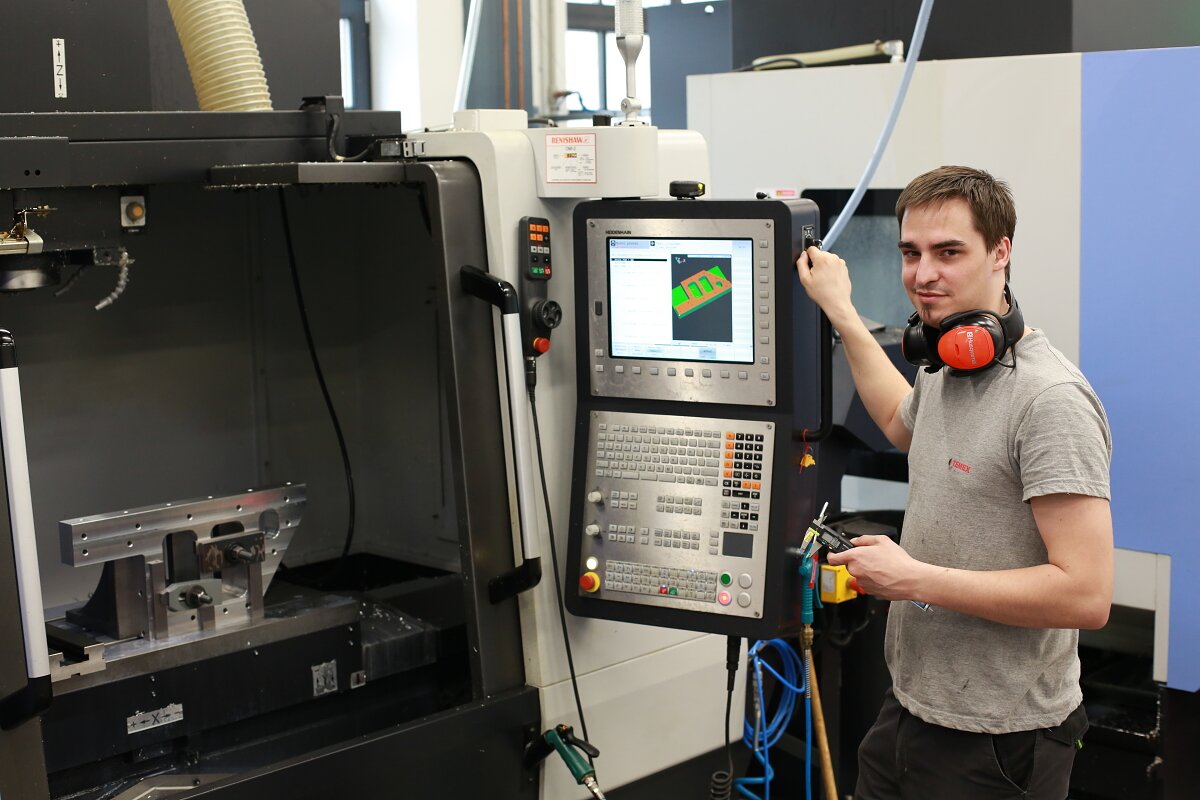

Production

After the customer approves the design of the machine, the parts go to the machine shop. The shop has 6 CNC machining centers, including a 5-axis milling machine, 2 lathes, an EDM wire cutter and other specialized equipment. They allow us to quickly and accurately produce unique parts according to the 3D production documentation.

Assembly

The mechanical assembly of the machine or line then takes place in three specialized halls.

The electrical assembly center provides services for the design and construction of switchboards and takes care of the installation of electrical equipment throughout the line.

Startup

Finally, the programmers from the automation center arrive and conduct the initial startup of the machine. Together with the assembly team, they carry out adjustments to the line and equipment in order to ensure the required production parameters are met.

Warranty and post-warranty service

Our services do not end after the working component is handed over to the customer. We offer warranty and post-warranty service, including non-stop service. In addition to basic operator training, we also offer certified training for maintenance workers in the PLC programming of automated equipment.

As a supplier of comprehensive units in automation, machines, air conditioning and ventilation, we also supply all services related to these activities. We accept orders not only for the delivery of comprehensive units, but also for the individual services of designers and programmers, experts in the parameterization and design of drives, inspection technicians (initial inspections and issuance of declarations of conformity) and plenty more.