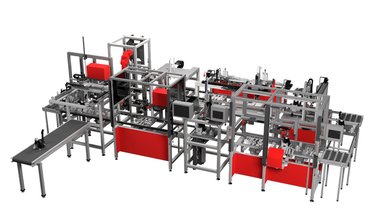

Towing equipment assembly line

New production variant of the original line for manufacturing a new type of towing equipment

Basic parameters

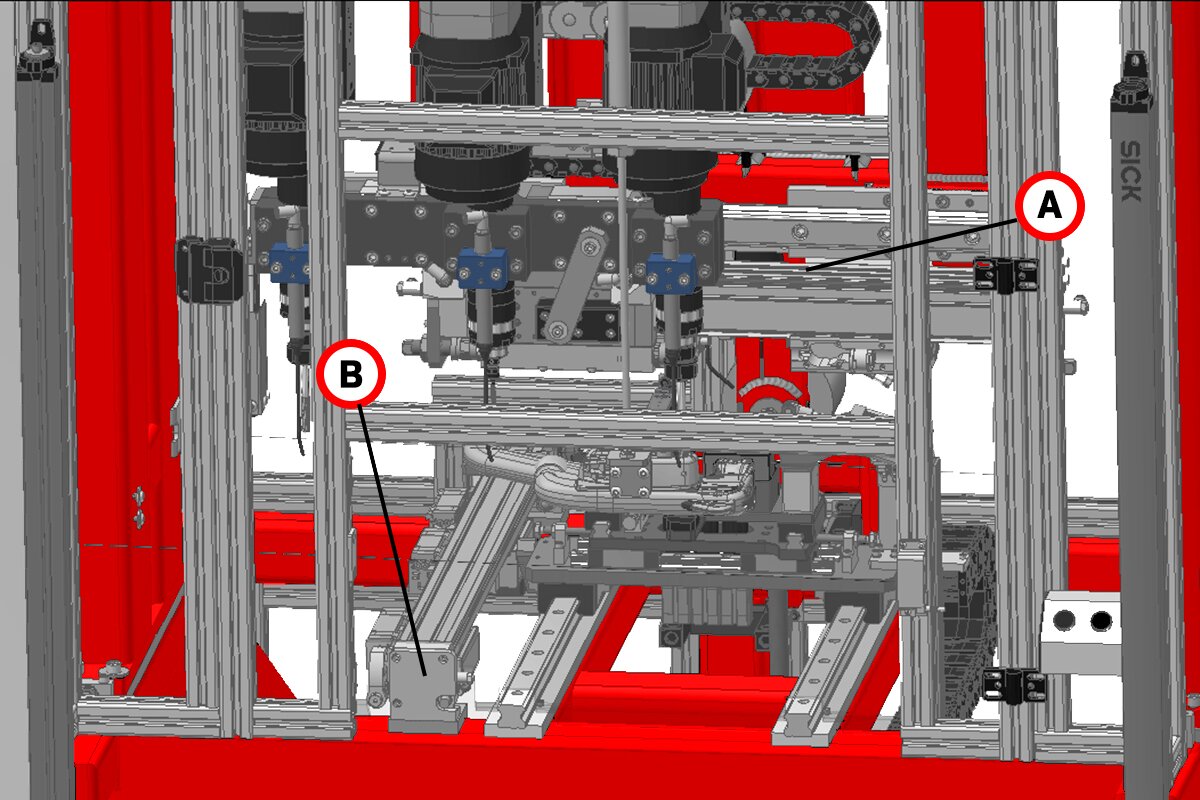

Part of the line: A – axis 1, B – axis 2

ad 2.

ad 3.

ad 4.

ad 5.

ad 6.

ENLARGING THE ORIGINAL TEMEX LINE WITH A NEW PRODUCTION VARIANT

Name of contract: Towing equipment assembly lines

Term of delivery: 2018

SPECIFICATION:

The project was implemented at the request of the customer to expand the existing line supplied by Temex in 2012 to manufacture a new type of towing equipment.

SOLUTION:

It was necessary to devise such a solution that kept both the current cycle and production of the machine. Replaceable jigs had to be produced and the line adjusted to them on site so that a quick change in jigs could be done in the shortest amount of time.

DESCRIPTION OF THE AUTOMATED PROCESS:

1. Turning:

• Replacing the current air-operated rodless cylinders for X-Y workpiece movement (axis 1 and axis 2) – turning units for FESTO electric drives, including the control unit.

• Adding new components to the electrical switchboard.

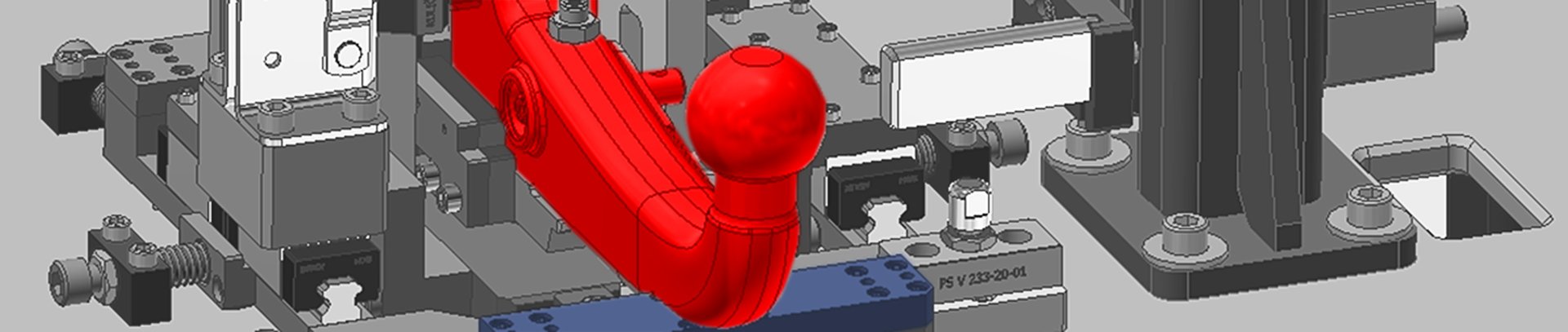

• New mechanical ball support for the new S383.

• Reprogramming machine operation for all existing types.

• Adding new type of towing equipment to the SW.

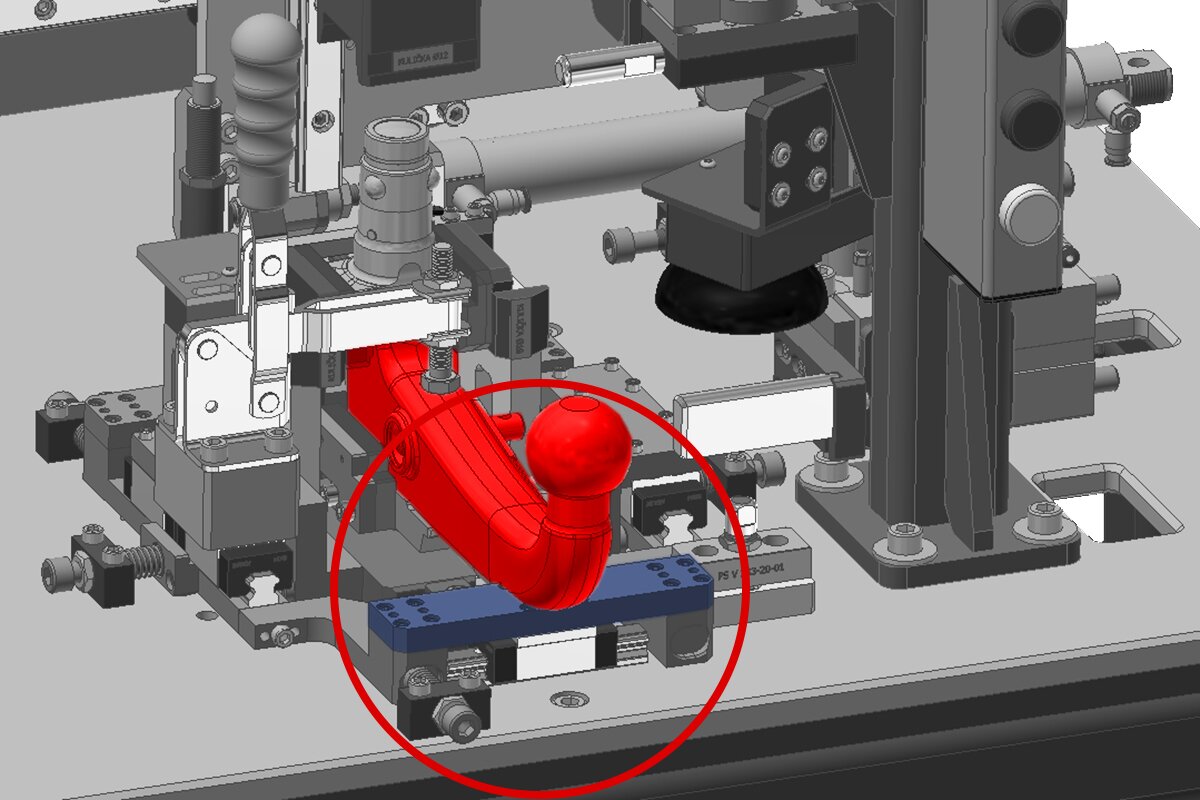

2. Ball attachment:

• New ball support.

• Redesign of the front attachment system – collision with the new S383 – delivery of the manual clamp, including a holder.

• Adding new type of towing equipment to the SW.

3. Carousel:

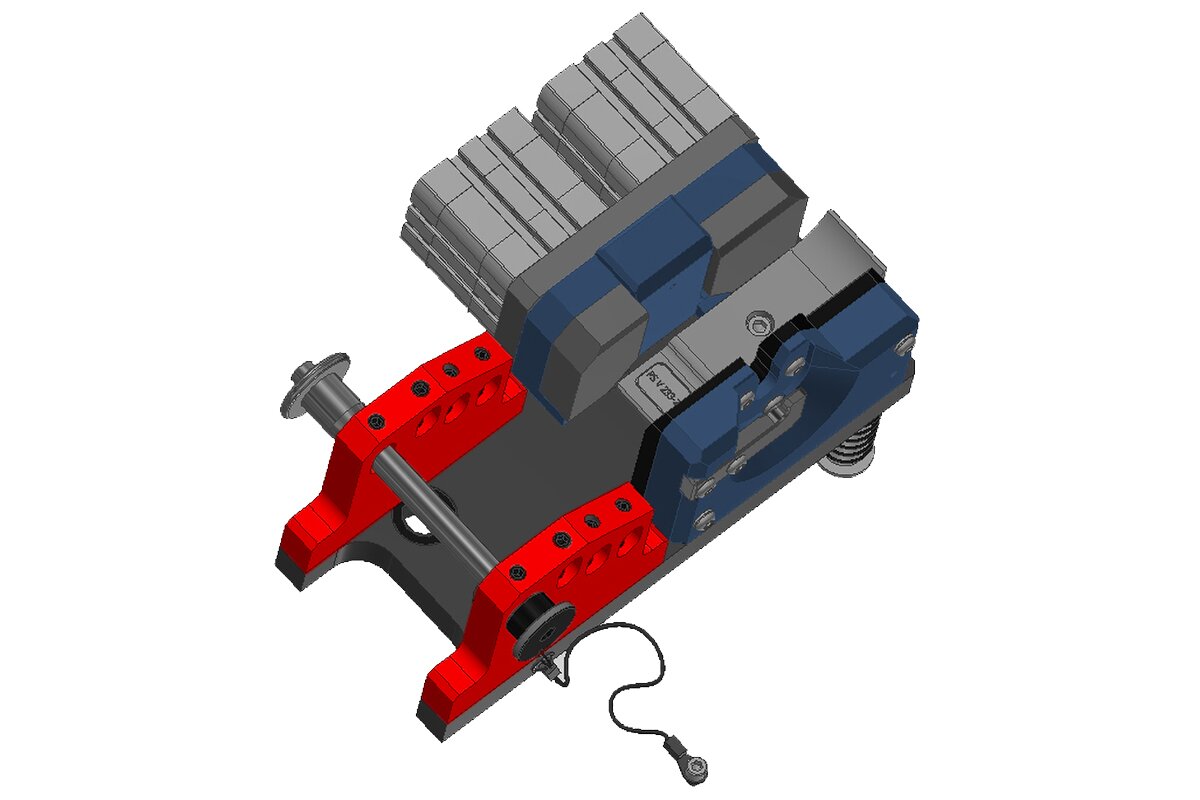

• Production of new inserts for 2 loading jigs.

• New system to support the end of the towing equipment in place of the hitch – integrated into the new support insert.

• Adding new type of towing equipment to the SW.

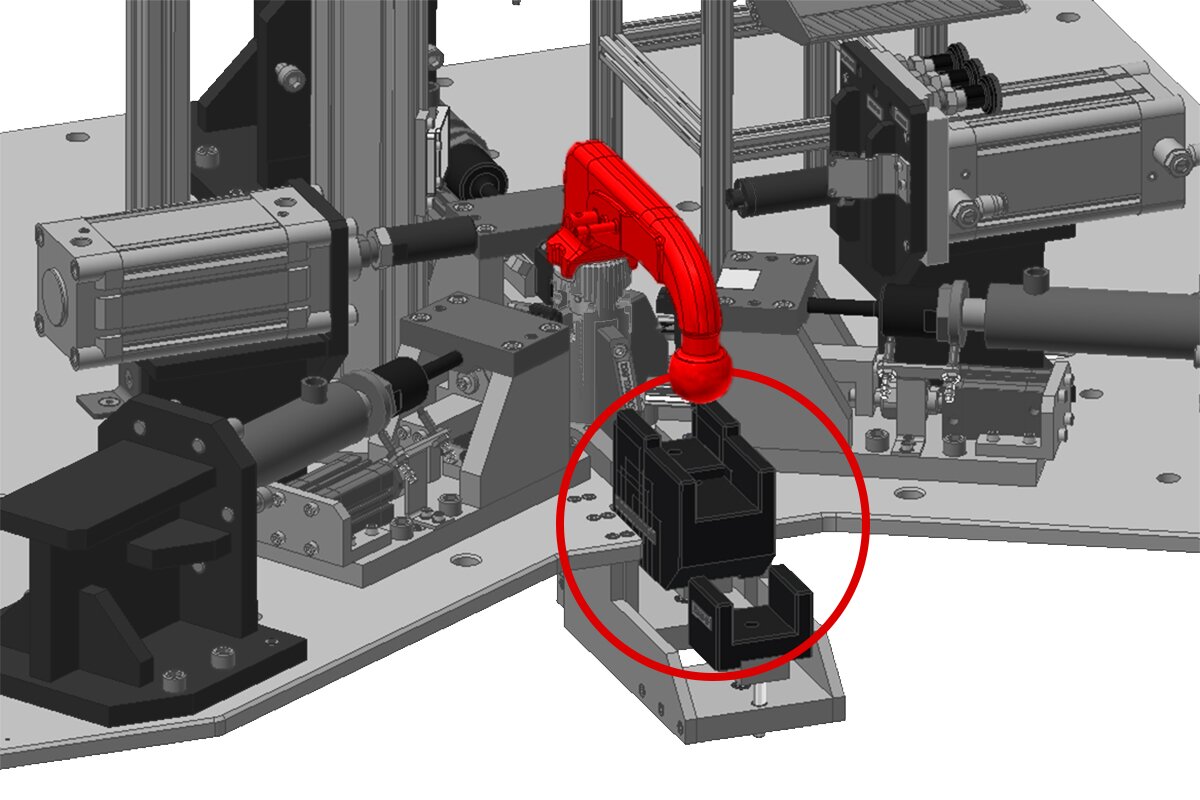

4. Pressing of pins:

• Delivery of a new support cube for the actual ball of the towing equipment.

• Adding new type of towing equipment to the SW.

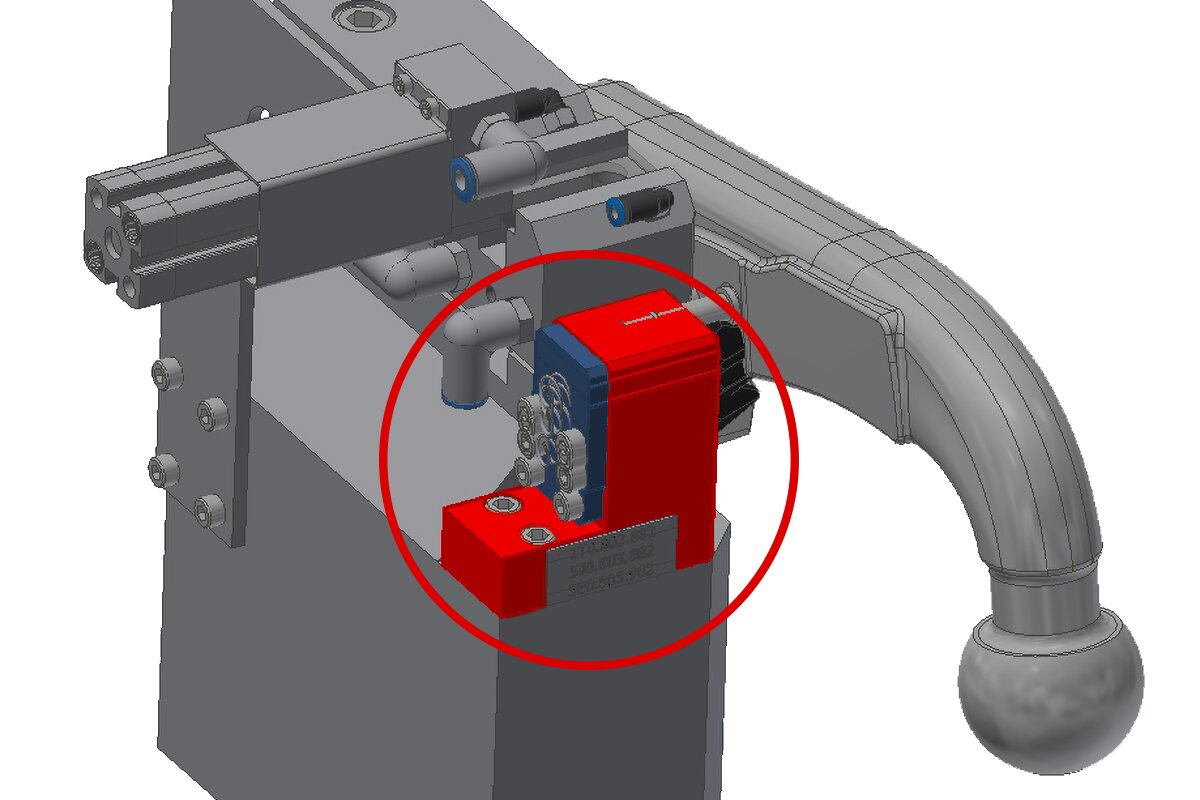

5. Lever axis drilling:

• Delivery of a new centering support jig.

• Adding new type of towing equipment to the SW.

6. Tester:

• Change in the position of the X-Y mechanism of the loading jig due to a collision with the towing equipment.

• Production of new inserts for the loading jig.

• Production of a new control lever depressor.

• Adding new type of towing equipment to the SW.

Key benefits of our solution

- Saves financial costs for the production of a new line

- Eliminates work-related accidents during the manual production of towing equipment

- Saves financial costs incurred for the manual work of employees

- Reduces scrap