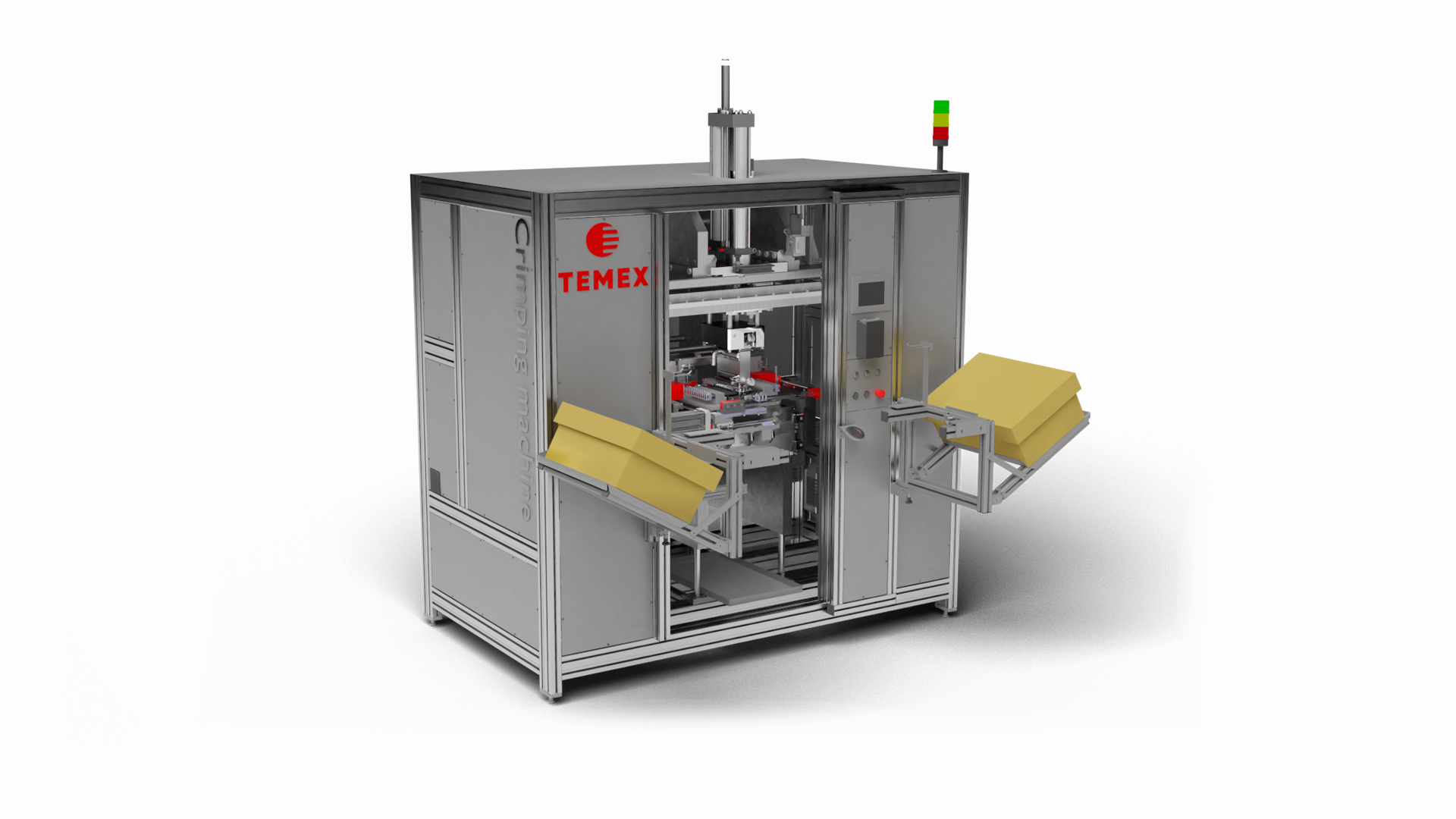

Radiator crimping

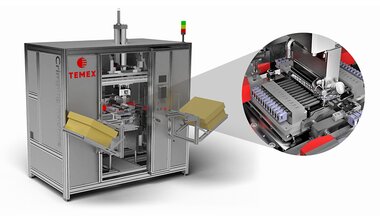

TEMEX crimping machine = firm and precise connection of plastic lids to the radiator core

RADIATOR CRIMPING MACHINES – BASIC CHARACTERISTICS

- Crimping machines are used to make a solid connection (crimping) of plastic lids with the radiator core.

- TEMEX crimping machines are designed to enable the crimping of different types of radiators of the same concept using interchangeable tools.

- Each machine is always customized according to the customer's requirements.

- Our crimping machines are used worldwide to assemble radiators for almost all major automotive brands such as VW, AMG, TESLA, BMW, HONDA, VOLVO, FIAT, FORD and others.

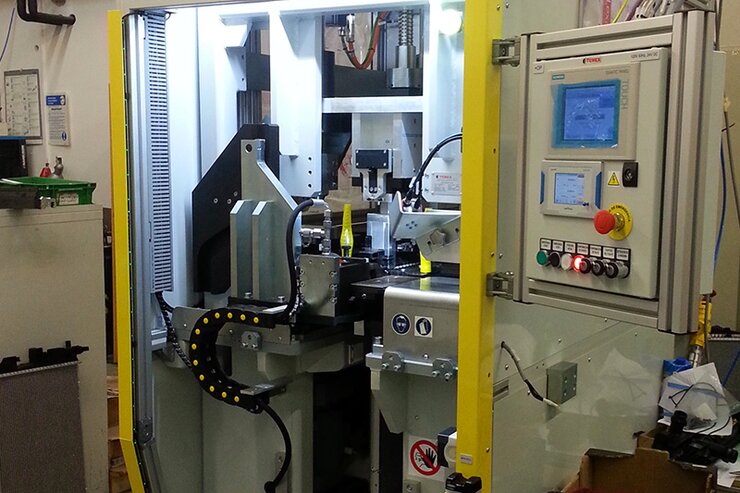

- The machine works as a stand-alone workstation and can be easily integrated into existing production flow.

CRIMPING MACHINE TYPES:

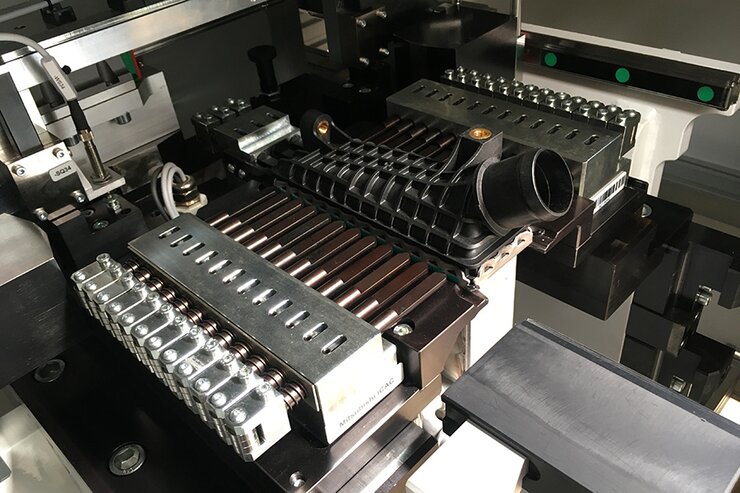

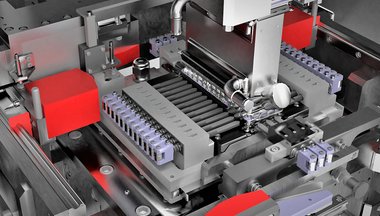

• Finger style crimpers – suitable for all types of coolers, most commonly used for CAC and iCAC radiators.

• Plate style crimpers – suitable for all types of radiators, most common for LTR and RAD radiators.

RADIATOR CRIMPING MACHINES - PRODUCTION PROCESS CONTROL

- All crimping machines have various types of control mechanisms to prevent the creation of non-conforming products due to a poorly executed crimping process.

- By default, the type and orientation of the inserted lid in the machine is checked by means of a camera sensor, e.g. Keyence.

- Depending on the type of tool, the orientation of the radiator core, the color or the presence of a lug is then checked (again e.g. with a Keyence camera sensor or Keyence LR-W or LR-Z sensors).

Key benefits

- Minimization of scrap down to 0%

- Shortening production cycle time

- Elimination of manual operator input into the crimping process and the creation of NOK units

- Modularity of the equipment and the possibility of assembling multiple coolers of the same type on one machine

- Individual adaptation to the client's requirements