EGR valves and coolers

TEMEX lines for the assembly of EGR valves and coolers = accelerated and improved production of exhaust gas control systems´ main components

EGR VALVES AND COOLERS

IN BRIEF

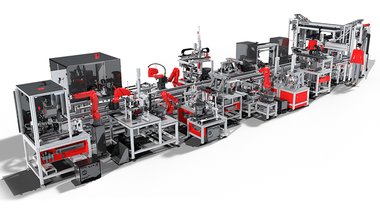

We have been developing and manufacturing equipment for the automated assembly of EGR valves and their coolers in TEMEX since 2014. During this time, our customers and we have identified weaknesses in the production process and replaced them with appropriate modern technologies that significantly eliminate scrap and shorten production time. We manufacture and supply both stand-alone equipment for the automation of certain parts of the production process, entire semi-automated and fully automated lines for the assembly of EGR valves, and two generations of lines for the assembly of coolers for EGR valves.

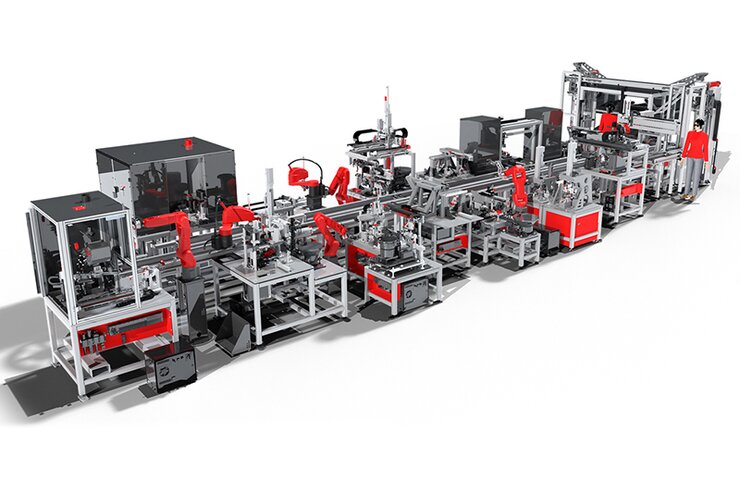

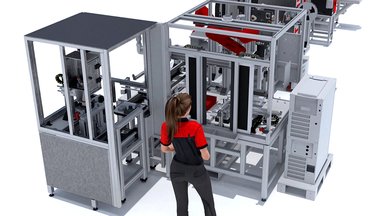

LINES FOR ASSEMBLING EGR VALVES – BASIC CHARACTERISTICS

Automated line

- Fully automated solution of our design

- Minimizing the number of operators needed to operate the line (2 people)

- Assembling the EGR valve on the order of tens of seconds

- Maximizing the use of robotics – at the beginning of the process, the operator only puts the parts on a pallet and at the end of the automated process removes a finished valve, assembled and tested

- Ensuring the presence and correct placement of parts on the pallet using a vision system

- Actively using ionized blowing + automatic cleaning and activation of the surface of parts using plasma technology

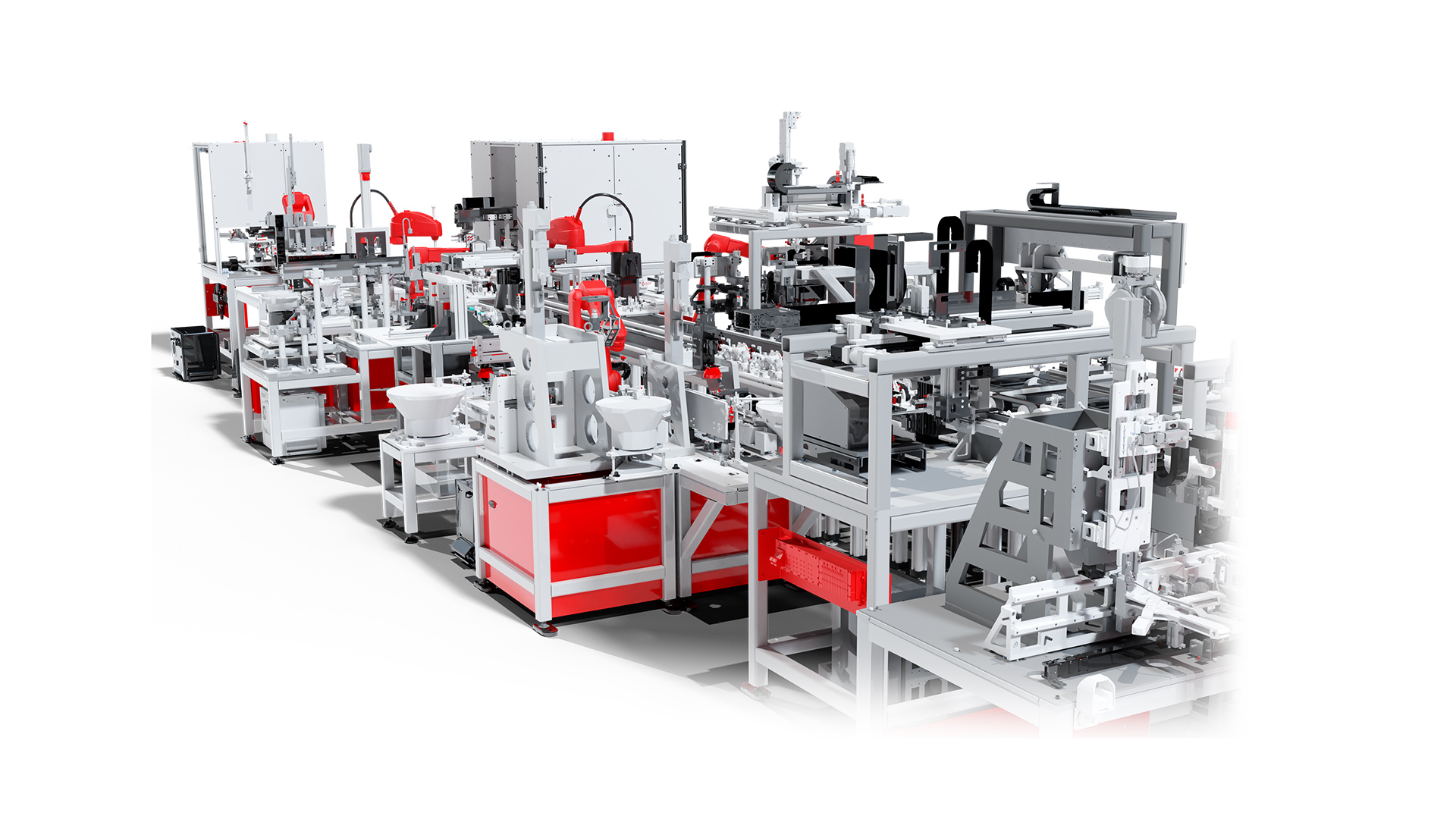

- The process of assembling the valve is fully automated; the line carries out the operations independently, such as:

– Handling, insertion, positioning, centering, mounting

– Pressing, welding, screwing, gluing

– Continuous inspection of the presence and positioning of parts using vision systems

– Continuous airtightness tests of components

– Automatic EOL test, including chip programming for the valve

– Laser marking of DMC codes, verification using an automatic scanner, and entering it in a traceability system

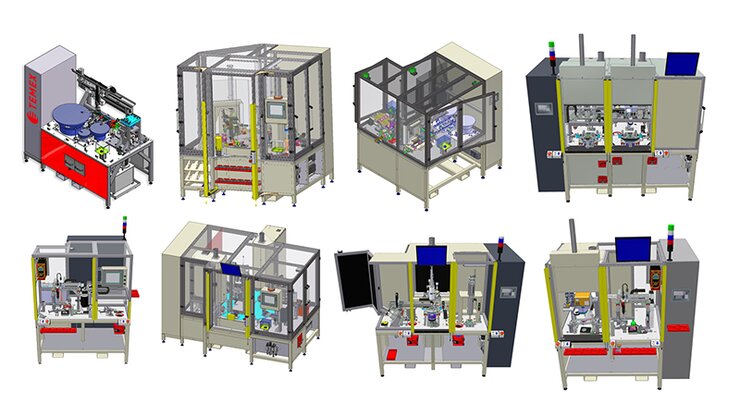

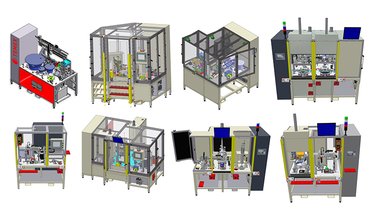

Semi-automated line

- Design of the line incorporates automated and semi-automated stations of our construction

- Operator-manned stations, each with several separate workstations

- Possible adaptation of workstations to assemble more variants/generations of the valve

- Operators only load individual parts into the jigs. Other processes at the stations are fully automated

- Having the line consist of separate stations makes it possible to install and use automation for only part of the assembly process

- Separate stations for testing the tightness and operation of the valve – up to 3 test stations

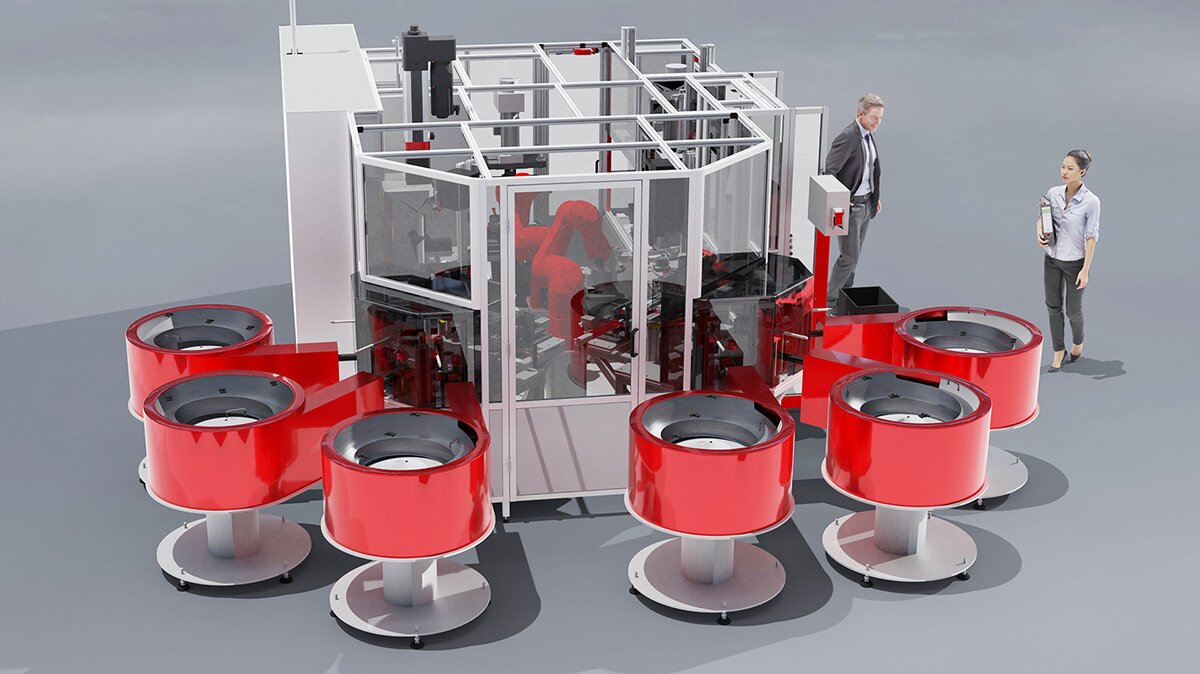

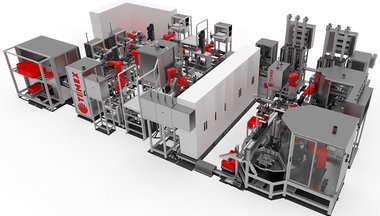

LINES FOR ASSEMBLING THE EGR MODULE COOLERS – BASIC CHARACTERISTICS

- Automated workstations operated by robots

- Only one operator for loading components and removing finished pieces

- Service robots with grippers of our unique design

- Maximum automation of the assembly process:

– Vibrating input feeders

– Robotic loading, orientation, and manipulation of tubes

– Pressing, pasting, tempering, and threading through caps

– Laser welding and marking of DMC code

– Camera vision systems

Key benefits of our solutions:

- Minimization of scrap to the threshold of 0%

- Assembling the product in shortened times – minimizing the line cycle

- Elimination of manual inputs into the assembly process and creation of NOK pieces

- Human resources savings

- Individual adaptation to the client’s requirements