Large conveyor line with helio testers

The line is used for the assembly and testing of canisters for the automotive industry (fuel system). As the canister passes through the line (conveyor system with pallets), individual components are assembled and a helium test is performed to check for leaks.

VELKÁ DOPRAVNÍKOVA LINKA S HELIO TESTERY

The device is designed as a single unit. It consists of seven individual workstations connected by conveyors and a robotic station with helium testers.

DESCRIPTION OF THE DEVICE

The line is equipped with a system of conveyors (4 conveyors + 2 conveyors on lifts), which are used to automatically move pallets between individual workstations (1 conveyor = 1 control motor). There are 15 pallets in total. These pallets are equipped with loading nests for inserting the assembled and tested product.

Workstations 1, 2, 5, and 7 are accessible to the operator in any selected mode (they are spatially open). The other workstations (3, 4, 6, robotic station with helio testers) are equipped with doors fitted with safety locks. The door locks are locked at all times when automatic mode is active. The lock is unlocked (allowing the door to be opened and access to the workstation) by switching the key switch on the DT1 control panel from the AUT position to the SERVICE position and unlocking the door on the HMI panel. The robotic station is equipped with an Euchner lock, which unlocks the door when the button is pressed.

Workstations 1, 2, 5, and 7 are equipped with safety light curtains. The entire device is equipped with a system of 9 emergency buttons designed to increase the safety of the device and its operators. The lighting of the individual workstations on the line is provided by a system of LED lights, which can be switched on/off using a button on the HMI panel.

WORKSTATION 1

Slouží k zakládání testovaného produktu do zakládacího hnízda, které je umístěno na paletce. Paletka je součástí dopravníkového systému. Lze ji podle typu vyráběného produktu měnit (tím se mění i zakládací hnízdo). Záměnu paletek lze provádět na pracovišti 7 (pro tento projekt jsou k dispozici dva druhy paletek).

WORKSTATION 2

This workstation is used for a different type of canister.

WORKSTATION 3

It is outside the machine, completely closed to the operator, and fully automatic. It is used to pick up the canister from the pallet for collection by the robot. The robot takes over the canister and the entire workstation returns to its starting position and waits for the arrival of the next pallet with a canister.

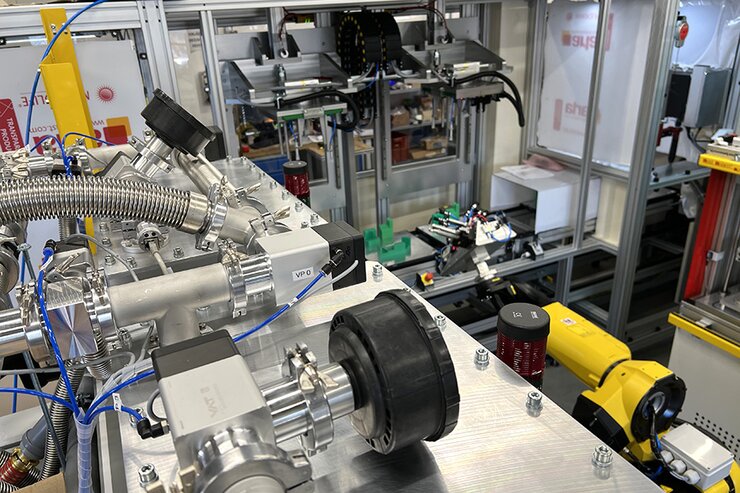

Robotic workstation with Helio testers

This workstation is fully automatic. It contains one Fanuc robot and four Helio testers with a control unit and control panel. The robot performs the Pick and Place function here. It picks up canisters from station 3 and places them in one of the four free Helio testers. It then removes the tested pieces and transfers them to station 4. If the tested piece is found to be NOK, it is taken by the robot to the NOK box.

The Helio testers are divided into two cells on the left and right sides and have a beacon for evaluating the tested piece. Green – The tested piece is OK, Red – The tested piece is NOK, Blue – The tester is ready.

WORKSTATION 4

This workstation is used to remove the tested piece from the robot and then place it on a pallet.

WORKSTATION 5

This is a reserve workstation. Therefore, the workstation is shielded by Plexiglas.

WORKSTATION 6

This is a reserve workstation. It is outside the machine and is not intended for operation.

WORKSTATION 7

This workstation is used to assemble the filter to the canister using a Desoutter tightener.

NOK Box

It is used to store assembled and tested NOK pieces. It is located at the bottom of workstation 9 of the conveyor line. The NOK box area is marked with red covering. It is designed to hold at least 6 canisters. The NOK box doors are equipped with an induction sensor that records when the box doors are opened/closed. The placement of a piece is detected by an optical barrier.