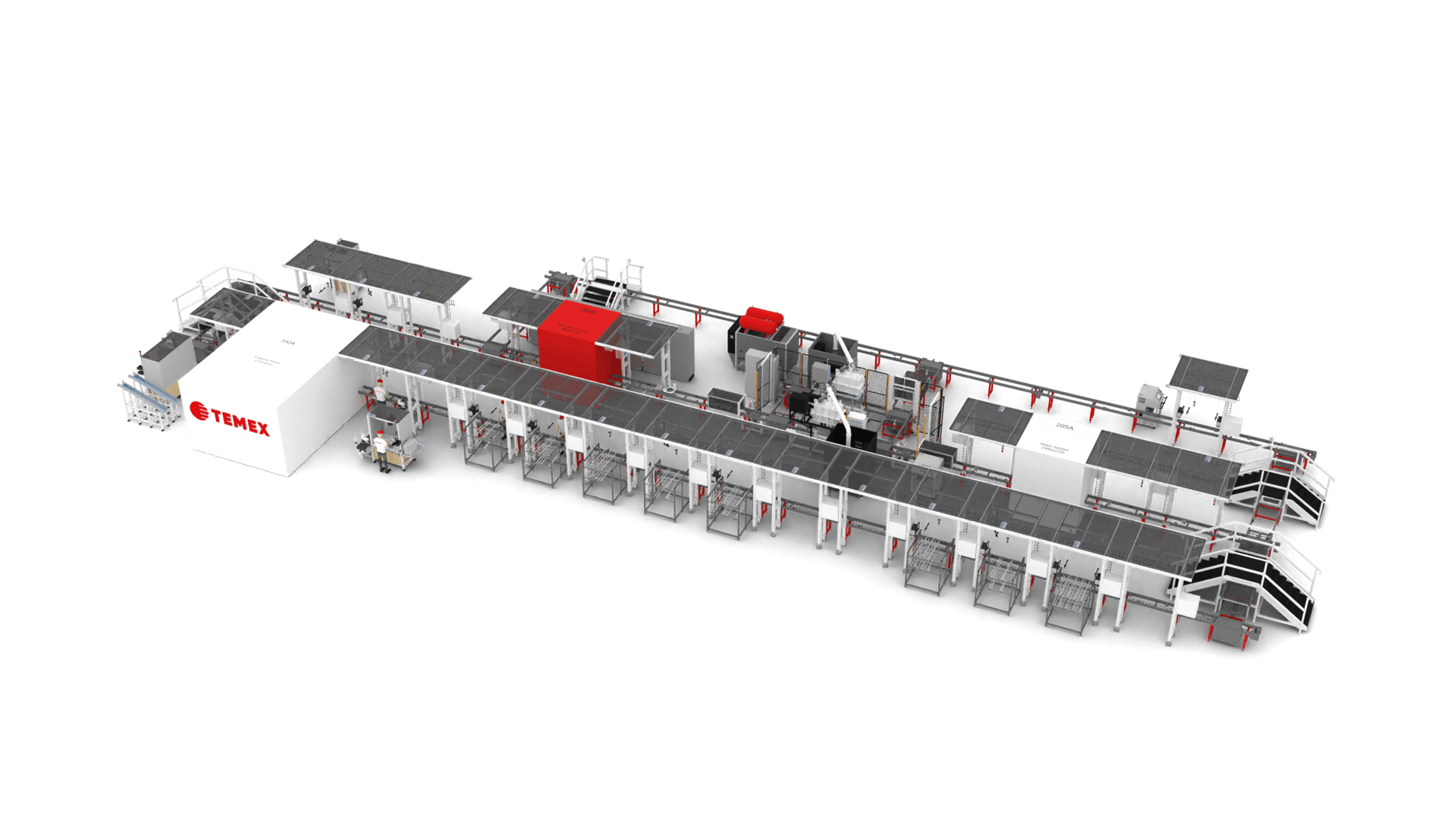

Assembly Line for HICE

The assembly line is designed as a combination of manual, semi-automatic, and automatic stations for the assembly of integrated cooling units for the automotive industry.

ASSEMBLY LINE FOR INTEGRATED COOLING UNIT

Realization date: 2024

Basic parameters of the assembly line:

Line cycle time – approx. 42 s, including pallet transfer with RFID reading max. 5 s.

Operation – 3 shifts/6 days/24 hours.

Production capacity – 85 pcs/hour.

Basic information

Manual stations are operated by individual operators who place the input parts into the pallets and assemble them using tools.

Semi-automatic stations are also operated by an operator who places and assembles parts in a pallet (e.g., cable harnesses with connectors) and then automatically starts the electrical testing process.

Automatic stations are fully controlled from the control system without operator intervention.

Individual stations are equipped with systems according to customer specifications (e.g., screwdriving system, Poka joke system, RFID, label printer and reader, robot, manipulator, and camera system).

In addition to the aforementioned stations, the production line is equipped with a conveyor section system with a rework station for any repairs to manufactured parts.

The line includes electrical switchboards for all stations equipped with the SIEMENS control system. Pneumatic treatment units with a FESTO series valve block (terminal) are located on the sides of the production line or stations. The equipment is controlled by a common touchscreen control panel located at the front within reach of the operator standing in front of the equipment and by separate control buttons at the individual stations of the line. The status is indicated by a colored beacon.