Educational line SMARTLINE 4.0

SMARTLINE 4.0 production line model – an advanced tool for teaching logistics and lean manufacturing in an Industry 4.0 environment

PRODUCT DESCRIPTION

This production line learning model is an advanced tool that effectively supports the adoption of lean manufacturing and logistics principles in an Industry 4.0 environment. The basis of this model is a physical line that is connected to a virtual warehouse and an MES system for production planning and control. There is also an economic system to evaluate the selected technologies and production processes. The individual systems are connected via SQL server to form a comprehensive production learning system. In addition to the physical line, students can also work with a digital twin, which allows them to simulate real production processes and to analyse and optimise procedures. This will give them the deeper knowledge and skills needed to apply lean manufacturing principles and better understand the differences between real and virtual lines and their importance in production planning.

PRINCIPLE AND OPERATION OF THE LINE

At the beginning, students are introduced to the market requirements - the quantity of products that need to be delivered to the market at the required price. On the basis of this information, they choose the technological process and select the appropriate machines for the individual robotic workstations with regard to price. They also have options such as quality control systems, service frequency or machine versatility. They have to carefully calculate everything in terms of technical possibilities, cycle time, cost and return on investment. After this analysis, students can purchase machines, plan production orders and start the actual production.

The entire line works in accordance with Industry 4.0 principles and is capable of personalized production. Based on scheduled work orders, material is automatically fed into the production process in the form of coloured pucks which, like the finished products, carry RFID chips. The pucks move along a conveyor belt where their codes are read by RFID readers before each production operation. A higher-level system, supported by an SQL database, then decides whether or not the material will be processed at a particular location based on the production process. All the information about the manufacturing processes performed is stored in the SQL database and students can verify it online at any time using QR codes on their phones. On the assembly line, pucks are assembled according to production orders into the final product, which is then transported to the virtual warehouse. Students can choose the layout of the virtual warehouse.

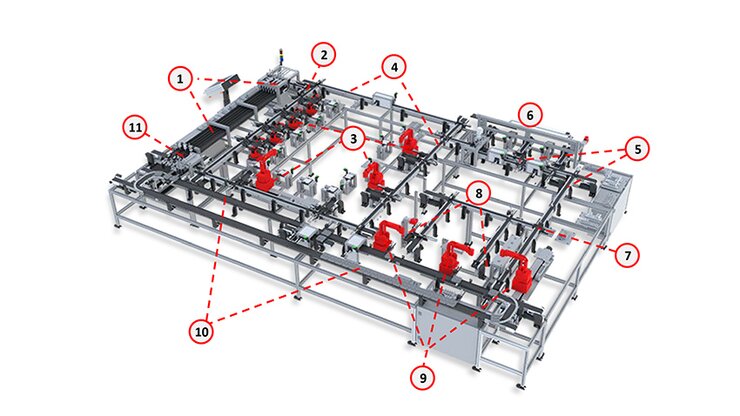

PARTS OF THE LINE

1 – Conveyor warehouse of input material

2 – Automated dispensing of input material

3 – 3x production operation centres (7 robots, 12 machines)

4 – Production conveyor circuit

5 – Central conveyor

6 – 2x output inspection workstation (1 robot on linear travel)

7 – Redistribution intersection

8 – 2x LIFO bins, 1x FIFO bin

9 – 3x robotic picking stations

10 – Oběžný dopravník na paletky

11 – Depalletizing warehouse

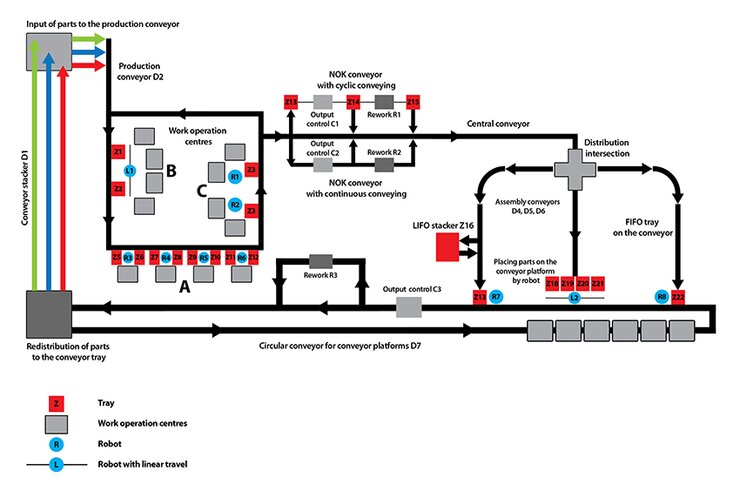

Example topology of the IDL (Intelligent Transport and Logistics) Testbed

FUNCTIONS AND FEATURES IN A NUTSHELL

Teaching lean manufacturing and logistics: The model enables practical learning of lean manufacturing and logistics principles.

Industry 4.0: The line operates according to Industry 4.0 principles, including personalized production and the use of RFID chips for material tracking.

Comprehensive system: Linking the physical line with the virtual warehouse, MES system and economic system.

Digital twin: The ability to simulate and optimize production processes using a digital twin.

Automated material flow: Automated material picking and movement using conveyor belt and RFID readers.

Flexible warehousing: Virtual warehouse with the possibility of customization and use of different storage and logistics technologies.

Economic analysis: Evaluation of production efficiency and return on investment.

TECHNICAL DATA:

Line dimensions: 6 220 mm x 3 922 mm.

Conveyor circuits: 4

Number of robots: 10

Control: Siemens PLC

Software: Client software (web application), server software with SQL database, Visual Components (for digital twin)