Production line for Paint by numbers Kits

Production line for Paint by numbers Kits, consisting of a machine for wooden frame assembly, a machine for stretching the canvas on the frame and nailing, and equipment for automated filling of the paint cups.

PRODUCTION LINE FOR PAINT BY NUMBERS KITS

Implementation date: 2022

The line consists of three parts (machines):

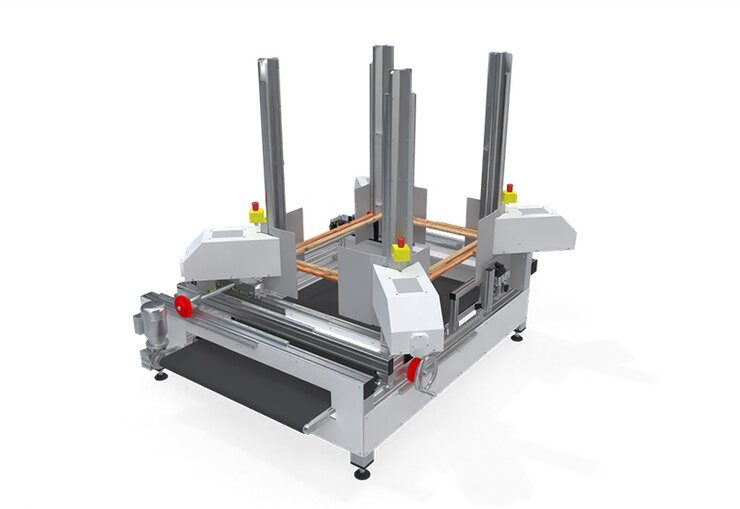

Machine A – wooden frame assembly

The machine is designed for the automated assembly of wooden frames. Using wooden strips with locks that are stored in trays, these strips are pressed together to form rectangular frames. These are then moved in front of machine B using a conveyor belt system.

The dimensions of the wooden frames are 400 to 800 mm (width), 500 to 1000 mm (length) and 15 to 20 mm (thick).

From the end conveyor, the images are ready to be inserted into machine B (image and canvas assembly).

The whole machine consists of several stations:

ST1 – Station for manual insertion of wooden strips and assembly of wooden frames

Conveyors – Transport of completed wooden frames in front of machine B (conveyors 1 to 5)

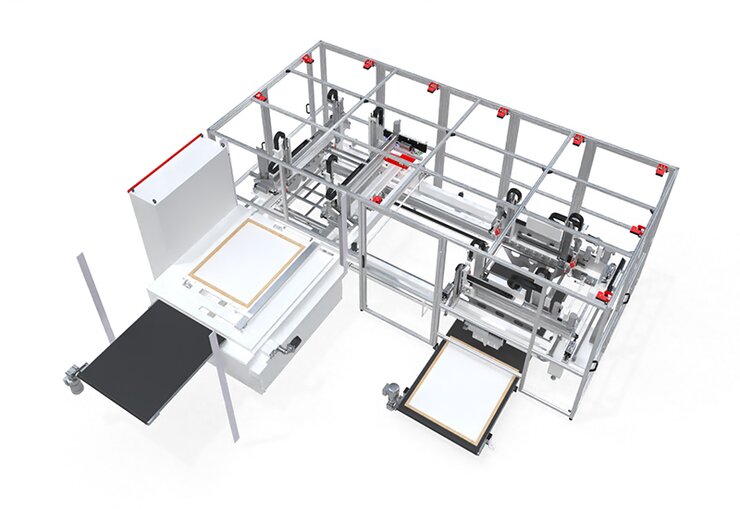

Machine B – Stretching the canvas on the frame and nailing

The machine is designed for automated stretching and nailing of the canvas on a wooden frame. The inserted canvas is stretched on the wooden frame, nailed and then transported on conveyor belts to the packaging. The dimensions of the wooden frames are 400 to 800 mm (width), 500 to 1000 mm (length) and 15 to 20 mm (thick).

From the end conveyor, the paintings are ready to be assembled as part of the whole product and inserted into the packaging machine (foiling).

The whole machine consists of several stations:

ST1 – Station for manual insertion of the canvas and wooden frame

ST2 – Station for automatic longitudinal stretching and nailing of the canvas to the wooden frame

ST3 – Station for automatic folding of all corners of the painting and transfer to the ST4 station

ST4 – Station for automatic transverse stretching and nailing of the canvas to the frame

Conveyors – Conveying the painting to be finished (conveyors 6 - 8)

Packing table with code readers

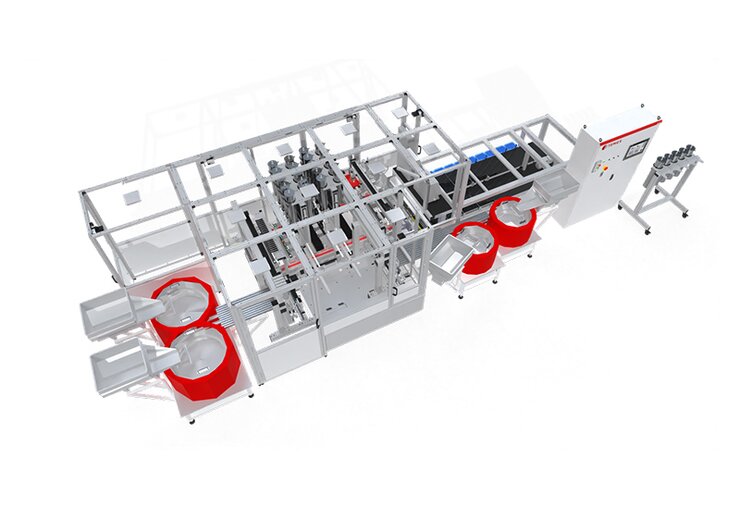

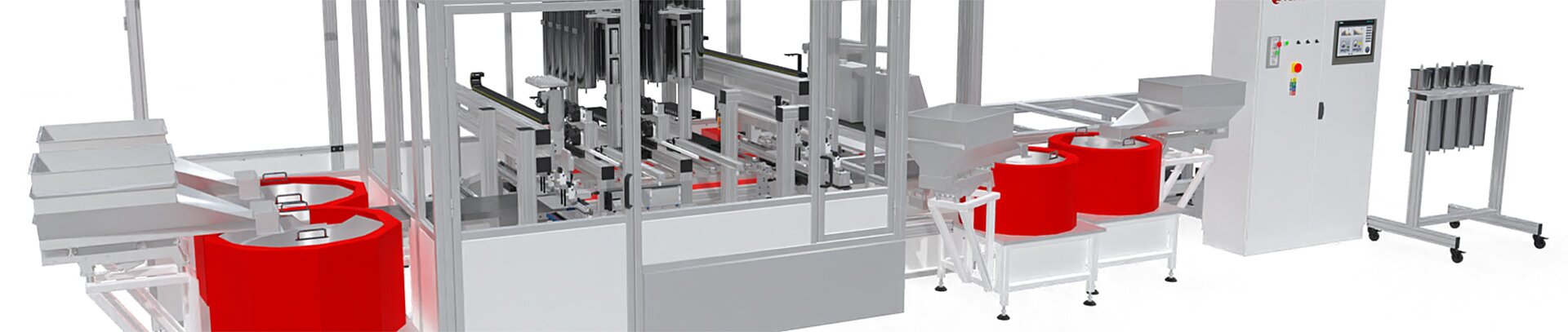

Machine C – Filling cups with paint

The machine is designed for the automated filling of cups with different colours. The machine can fill up to 20 cups with different colours, which are then labelled and printed with an adjustable code on the cup and lid. The cups are then put onto a conveyor belt where they are transported to individual OK boxes.

The whole machine consists of several stations:

ST1 – Removing the cups from the vibrating bar and placing them on the pallet of the chain conveyor.

ST2 – Filling up to 10 cups with paint.

ST3 – Filling up to 10 cups with paint.

ST4 – Removing lids and capping cups.

ST5 – Checking the correctness of the cup capping.

ST6 – Dropping incorrectly capped cups into the NOK box.

ST7 – Labeling of cups and lids by Inject.

ST8 – Chain conveyor with pallets for cups and its transport between stations.

Conveyors –Transport of filled cups to OK boxes.

Vibratory feeders – Transport of input material (cups, lids) to the machine.