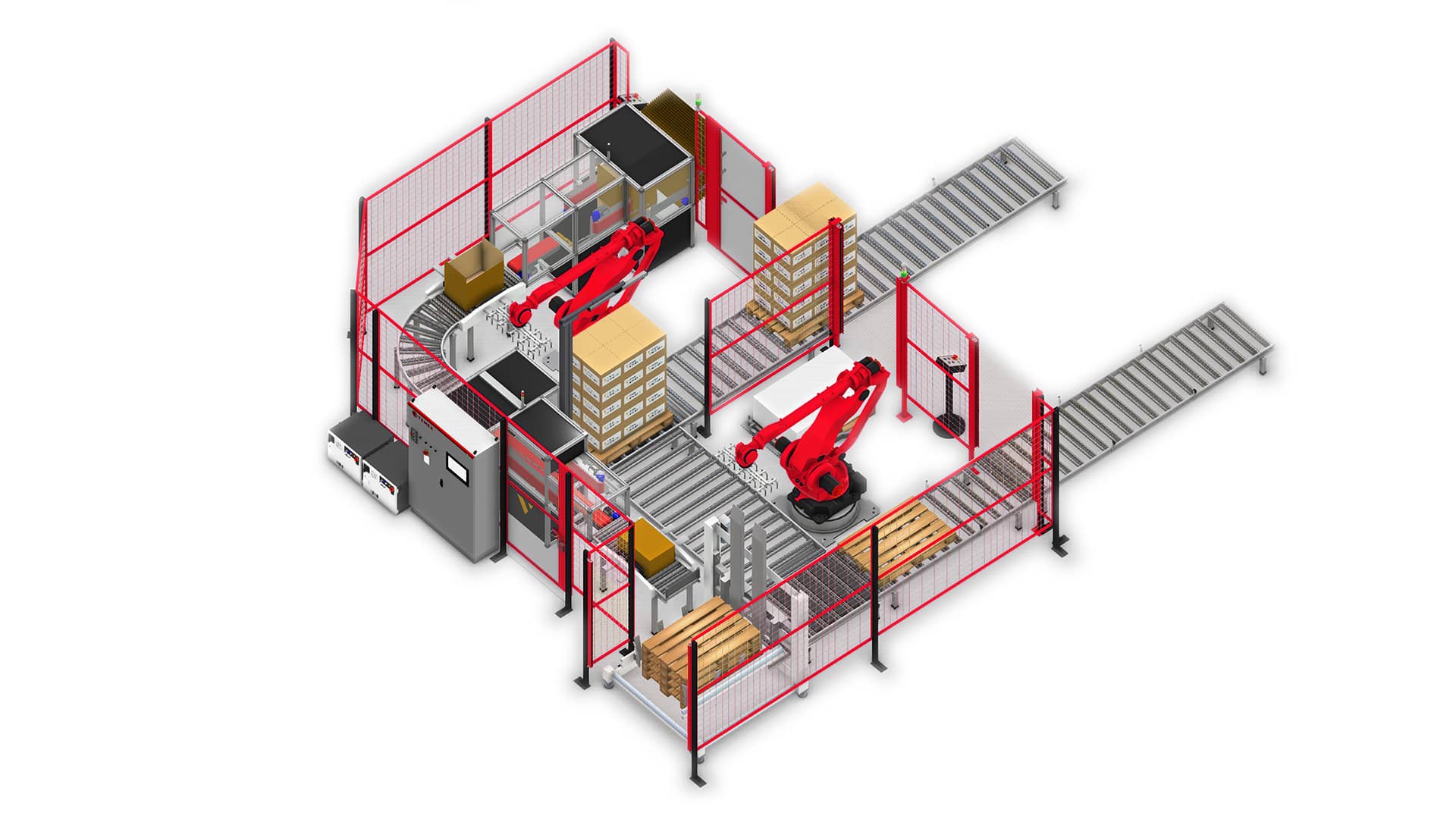

Compact line for depalletising and palletising

A study of a compact system for robotic depalletizing of individual packs of jars and doypacks from a pallet, insertion into master boxes and their re-palletization.

CASE STUDY COMPACT LINE FOR DEPALLETIZING AND PALLETIZING

Case Study: Automation of master packingTerm: 2022

REQUEST

For our partner in the food industry, we have prepared a study of a compact automated depalletizing, packaging and palletising line for packaging jars and doypacks into master boxes.The objective was to create a space-saving solution that would efficiently eliminate strenuous and monotonous employee activity and ensure maximum target performance (cycle-time).

OUR SOLUTION

The entire line design is based on 4 main hubs:

● Robotic depalletization of jar packs or doypacks boxes from the input pallet

● Folding of master cardboard boxes

● Robotic insertion of products into master boxes, closing, gluing and labelling of boxes

● Robotic palletizing of master packs onto the final pallet

Robotic depalletization of jar packs or doypacks boxes from the input pallet – an infeed conveyor, capable of holding at least two pallets of basic product packages, delivers the first pallet to the picking position. The 3D area sensor first detects the position of the products in each layer and then the robot with the vacuum gripper takes two complete rows of products and places them on the sorting conveyor. The conveyor then moves the products to the picking position for the second robot and also accurately lines up and aligns the individual packages in all directions. The empty pallets are one of the pallet sources for final palletizing, and after emptying, it moves to the final palletizing position for the filled master boxes.

Folding of master cardboard boxes – the unfolded cardboard master boxes are automatically removed from the tray, then folded into the basic shape and sealed at the bottom. The row of boxes is then moved by conveyor and fixed in the loading position.

Robotic loading of products into master boxes, closing, gluing and labelling of boxes – the insertion robot is capable of filling several master boxes at once using a special gripper with adjustable sections. This significantly speeds up the cycle time of the entire operation, thus ensuring one of the main prerequisites for maximum performance of the entire line. The filled boxes are transported by the downstream conveyor to the station for closing and sealing the master boxes. Each of the master packs is finally labelled with a label with defined information. The finalised master boxes then travel to the picking position of the palletising robot where they are centred and prepared for final palletisation.

Robotic palletizing of master packs onto the final pallet – the third robot within the line places the finished master packs according to the product type and the corresponding palletisation scheme into individual layers on the pallet. Between the layers, the robot inserts paper interleaves, which it takes from a separate tray. The completed pallets then leave the line using an output conveyor for further processing by the operator. The pallets themselves are either replenished from the destacking tray or the emptied pallets from the infeed conveyor are used.

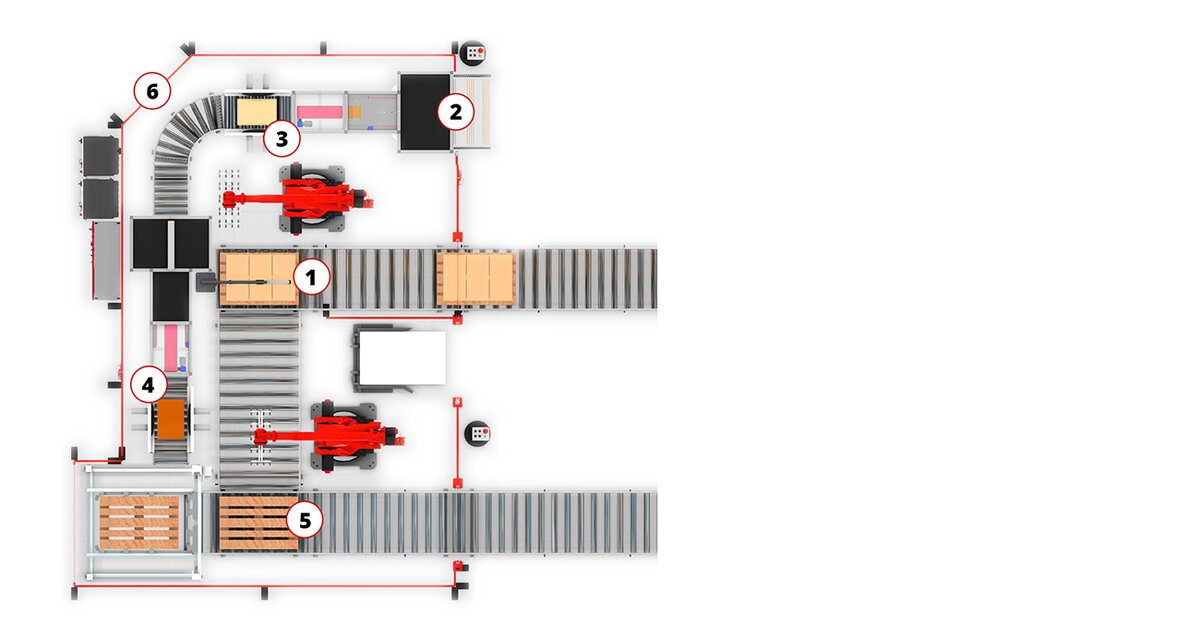

Basic line diagram and description

1. Depalletization of products from the pallet (boxes, four-packs of glasses)

2. Assembly of cardboard master boxes

3. Inserting products into master boxes

4. Closing, gluing and labelling of filled master boxes

5. Palletizing master boxes onto a pallet

6. Security fencing and safety features

ADDITIONAL DEVICES

The entire solution of this compact line can be supplemented with additional devices, both at the input and at the output of the line, according to the customer's requirements. At the input end, there can be a complete connection to the existing production line, so that the input pallets of products can be fed into the plant automatically, or individual products can be fed directly into the line.

The output part of the line can be easily and efficiently supplemented with elements such as automatic strapping machines or wrapping machines. In this way, pallets with master packs can be finalised completely without human intervention and are also immediately ready for dispatch or storage.

Contact us with your project and we will be happy to design a tailor-made solution for you.

KEY BENEFITS OF OUR SOLUTION:

- Elimination of exhausting and monotonous human work

- Efficient and reliable solution for maximum performance

- Upgradeable with additional components for even greater process automation

- Packaging of multiple product types

- Minimal space requirements