Ventilation and heating for a boiler room (Ledvice power plant)

The perimeter walls of the new B6 block were fitted with adjustable ventilation / heating louver segments.

VENTILATION AND HEATING OF THE BOILER ROOM OF THE NEW B6 UNIT

Name of contract: Ventilation and heating of the boiler room of the new B6 ELE unit (Ledvice power plant)

Term of delivery: 2013-2014

SPECIFICATION

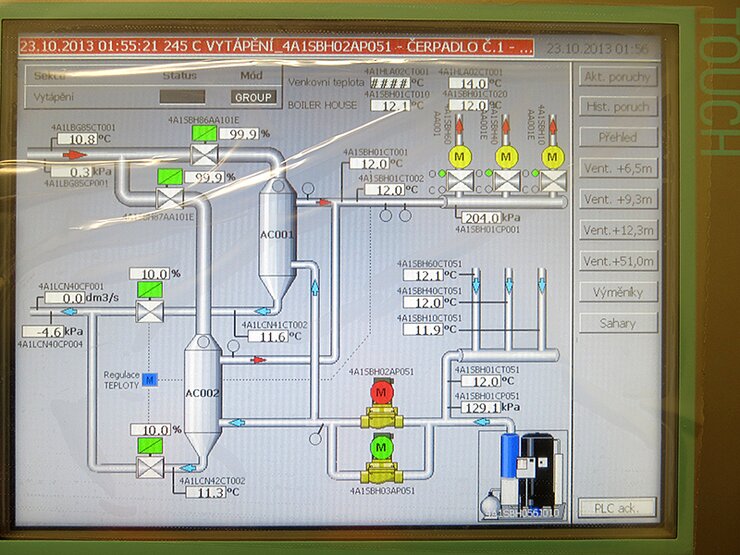

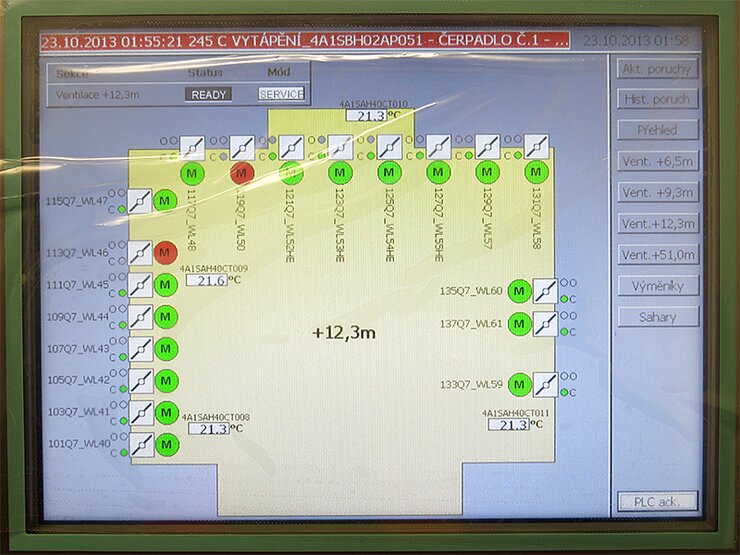

The subject of the project was a technical solution for the electrical and M&R delivery for a portion of the heating of the boiler room of the new B6 production unit of the Ledvice power plant (designation NZ ELE 660MW). This part of the project involved the power supply and control system for heating and ventilation in accordance with the required technologies. The connection of our control system (CS) to the DCS master system of the power plant was also carried out.

The electrical and control part was done as a comprehensive delivery, i.e. turnkey:

• Design, supply and installation of field instrumentation for individual measurements.

• Design, supply and connection of the heating/ventilation equipment and power supply.

• Design and supply of “+MX” transition boxes for individual drives, including installation.

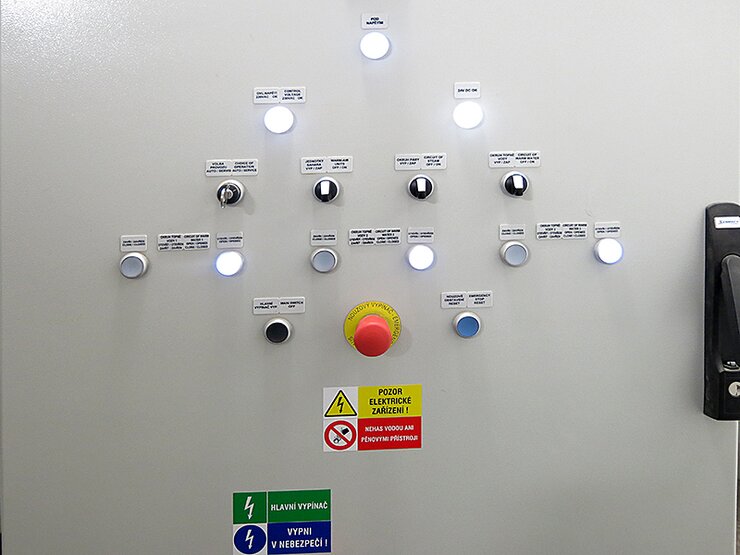

• Design, supply and installation of switchboards for heating/ventilation systems.

• Design, supply and installation of cable connections of all devices with switchboards.

• Design of HW configuration of the heating CS, including developing and supplying the software.

• Design of data networks (Profibus).

• Grounding, protective connections.

• Connecting the heating/ventilation equipment to the DCS power plant master system.

TECHNICAL SOLUTION OF THE EQUIPMENT

The entire technical solution of our part consisted of maintaining a required constant temperature in the inner space of the boiler room of the B6 unit with regard to the outdoor temperature and the operating mode of the boiler room, or the operating mode of the fluidized bed boiler and the seasons.

A new exchanger station was delivered to provide hot water for the heating loops. The perimeter walls of the new B6 unit were fitted with adjustable ventilation/heating louver segments. Based on these algorithms, the interior of the B6 boiler room is ventilated or heated through these segments.

⇒ Interesting

“In 2018, a new observation tower was opened at the top of the boiler room of the new B6 unit of the Ledvice Power Plant. At a height of 144, it is the highest observation tower in the Czech Republic and can accommodate a maximum of 40 people a day.”