Robotization

Up to 45% of the daily work activities that people get paid for today could be automated with currently available technologies…

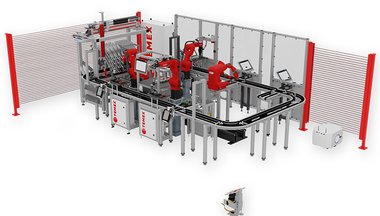

The term robotization can be thought of as an automatically performed technological or manipulative activity with the use of an industrial robot or manipulator, which is done in accordance with a predetermined procedure that sees the work cycle continuously repeated.

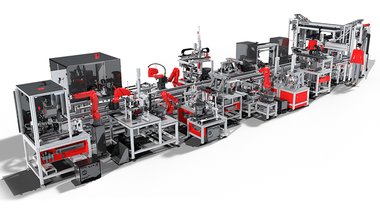

The increasing versatility and declining price of robots already allows their use in an ever-widening range of activities, where it is not efficient or realistic to purchase a large number of single-purpose machines. The possibilities of using robots have thus been considerably expanded.

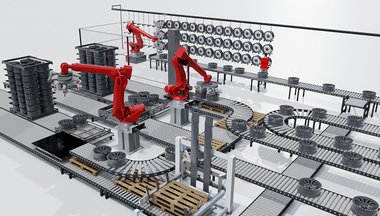

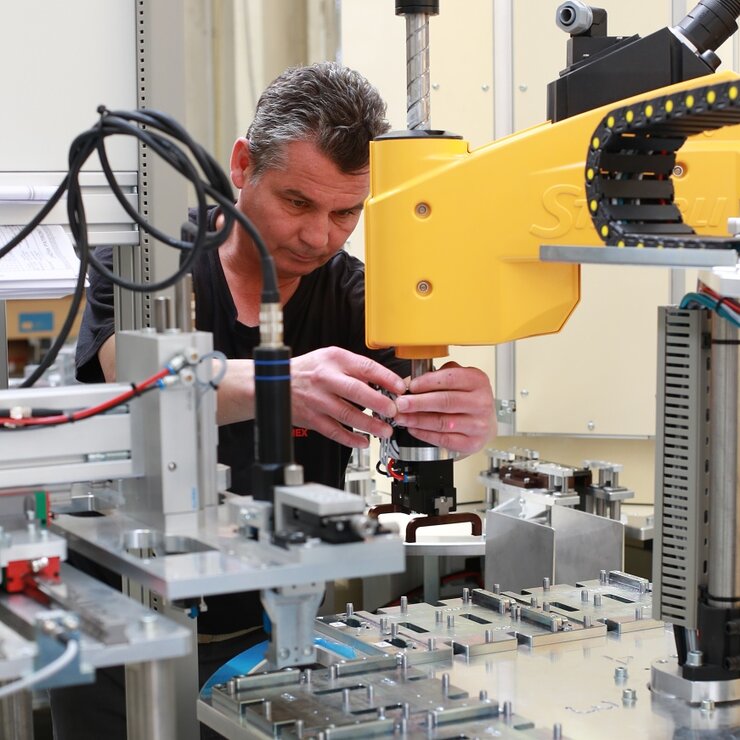

We can supply you with a robot that exactly mimics the sequence of movements of a human worker and is then able to repeat them endlessly. Thanks to fatigue-proof industrial robots, companies can significantly increase their production, and with minimal scrap. The greater involvement of robots could help reduce the shortage of workers that our industry suffers from.

What solutions can we offer you?

- Comprehensive automation – The overall process is automated and the workforce takes on the role of planning and strategic management.

- Partial automation – Only certain processes and functions are subject to automation, while the remaining phases of the process remain in human hands.

What types of robots can we deploy for you?

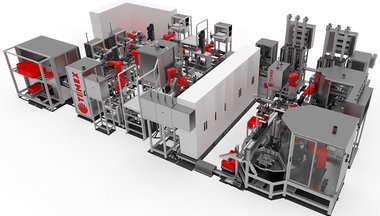

Choosing the right type of robot is crucial not only to achieve the required operation, but especially in view of the price you will have to pay for robotics.

- Manual manipulators are single-purpose and multi-purpose handling devices, controlled by humans. They are designed to multiply the strength and movement capabilities of the operator.

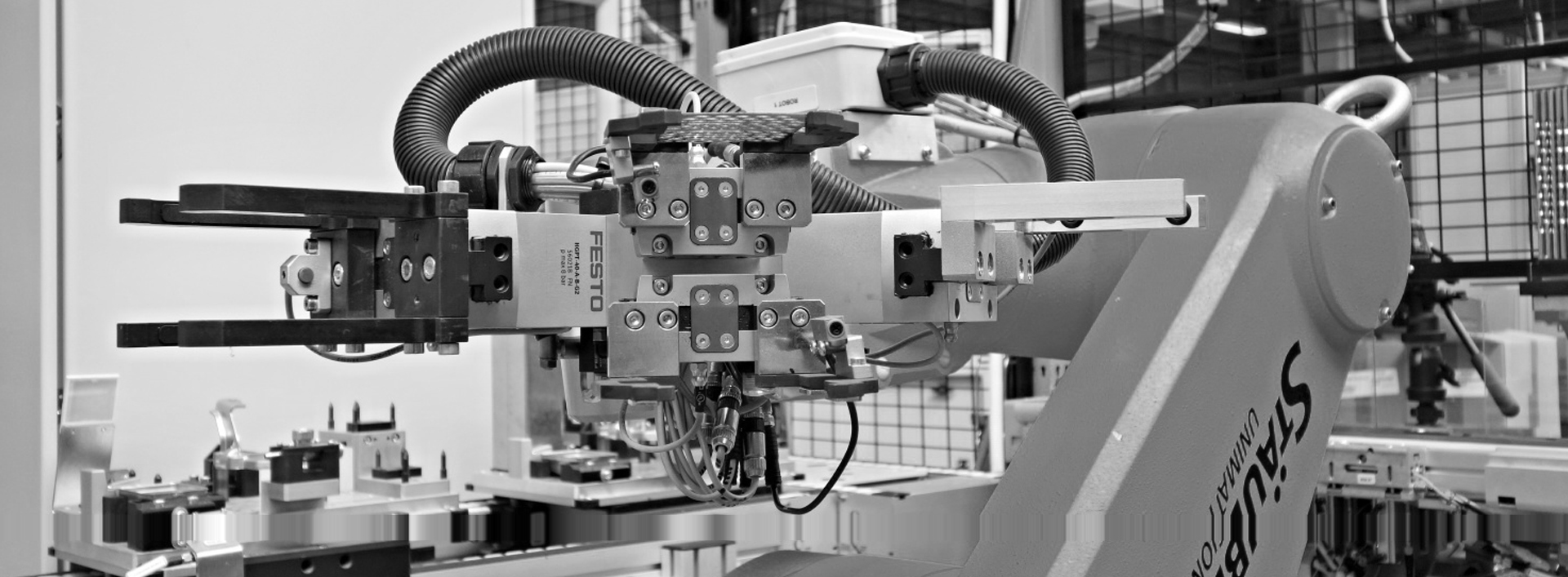

- On the other hand, manipulators with a fixed program (sequence) work automatically and without direct human participation. These robots are able to repeat predetermined work cycles based on several or many partial work movements.

- Manipulators with a flexible program follow a specified automated program, which, however, can be quickly changed by resetting the specified elements of the control system. These include, for example, industrial robots and cognitive robots. They are able to automatically create and modify the program of their activities according to the specified goals, with the help of communication with humans.

Each robot is equipped with peripherals, which can include a panel for manual control, drives for external memory, a terminal and, for example, a printer. The machine also includes a control system, which, according to the configured program, controls the robot’s operation by controlling its drives and other kinematic structures.

Why invest in robotics?

- Reduce operating costs

- Improve working conditions for employees

- Reduce scrap

- Replace human imperfection

- Improve the repeated quality and level of products

- Reduce material waste

- Increase production per unit of time

- Incomparably better flexibility of production lines

- Job savings

- Increase yield and profit