Separation and placing of plastic blisters and inlays

THOR = a sophisticated automatic device with multiple quality controls to ensure that only the correct blisters come out of the machine for further processing.

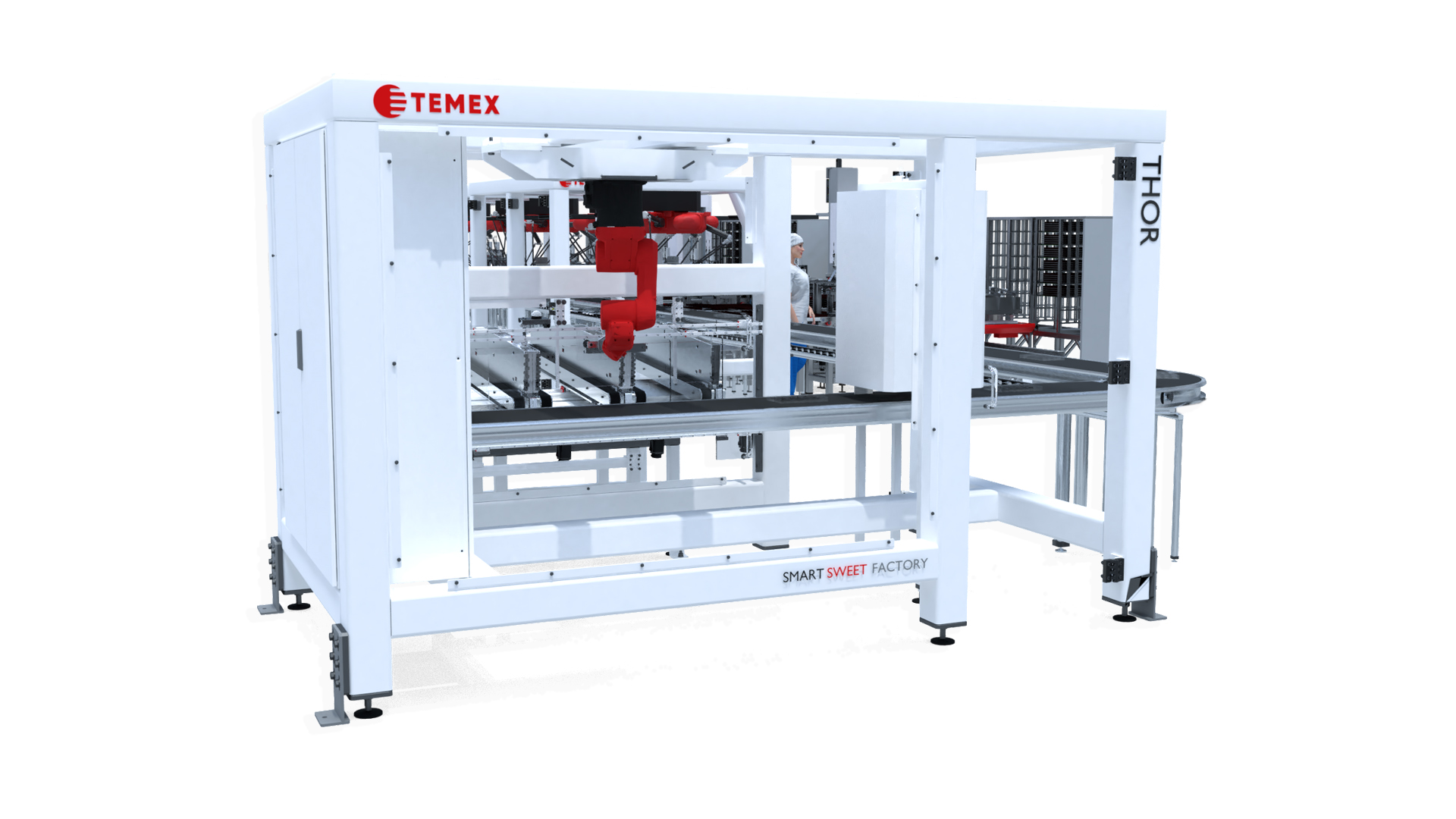

ROBOTIC MACHINE FOR SEPARATION AND PLACING OF PLASTIC BLISTERS AND INLAYS

WHAT IS THOR

THOR is a fully automated device for separating, removing and placing plastic blisters and inlays, applicable in a wide range of industries such as food, electronics and electrical engineering, pharmaceutical and medical device manufacturing and others.

CHARACTERISTICS

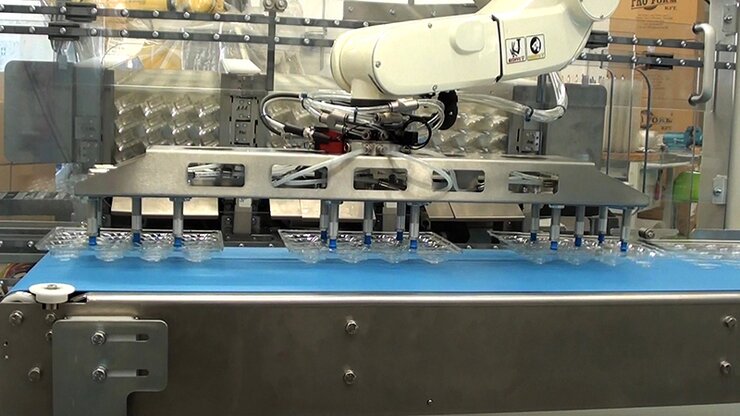

The device is able to load from 1 up to 3 plastic blisters very quickly and accurately onto a moving conveyor belt using a six-axis robot with interchangeable grippers and to check and separate any not-OK pieces within an integrated vision system. The machine is able to perform a 100% check of the correct blister type for all blisters being placed, correct orientation of the blisters, as well as locate and eliminate any defective or stacked blisters (2 or more joint pieces).

Significant modularity is an important added value of this device - in addition to the possibility to remove and load 1 to 3 blisters at a time, the width of the tray magazines, controlled by servo motors, is automatically adjusted by simply selecting a different production recipe/product type.

Likewise, changing grippers is easy, using QuickChanger technology, which allows quick change of products without the need to disconnect pneumatic and electrical circuits, with coding and feedback to the production system (without the correct gripper for the recipe/product, the system will not allow the machine to start).

The separation of blister packs is also fully automated with pneumatically operated separating knives, which separate only the last piece and leave the others blocked. The shifting of the columns with blisters in the trays is also controlled by servo drives, with the application of absolute metering. The equipment also automatically monitors the fill level of the bins on three levels - a maximum bin fill sensor, a minimum bin fill sensor to acoustically and visually alert the operator to the need to refill the bins soon, and a critical bin fill sensor, which when activated, brings the entire production facility to an emergency stop to prevent uncontrolled blocking of the equipment mid-cycle.

.

APPLICABLE BLISTER / INLAY DIMENSIONS

| Parameter | Dimensions | (in mm) |

| min. | max. | |

| Blister length | 181 | 323 |

| Blister width | 79 | 255 |

| Blister height | according to customer requirements | according to customer requirements |

DEVICE DIMENSIONS

| Height | 2 495 mm |

| Length | 4 250 mm |

| Width | 3 320 mm |

| Weight | 2 800 kg |

DEVICE PERFORMANCE

The speed of the device varies according to the selected application, or according to the type of blister and the number of blisters placed on the conveyor belt. A fixed parameter is the speed of robotic loading - the movement of the robotic arm from gripping to laying on the conveyor belt requires 2.25 seconds.

An example of device speed calculation:

The device separates and places 3 blisters from 3 tray magazines, where the blister spacing in the tray stack is 3 mm. Then:

- The loading speed of the device is 80 pcs of blisters/min.

- The unattended time is about 18 minutes at this speed (this is the autonomous operation of the machine, i.e. the time after which the blisters in the magazines run out).

HARDWARE

- OMRON Nx102-1200 control system

- OMRON 10“ touch panel

- Safety PLC OMRON

- Six-axis robot OMRON Viper 850

- OMRON servo drives and sensors

- OMRON Vision System + custom machine vision lighting Smart View

- PIAB vacuum technology

- All suction cup vacuum grippers with FDA approval

What makes THOR unique

- Fully automated machine, the operator only refills blisters

- Simple, fast and automated reconfiguration of the entire machine just by selecting a different recipe/product type.

- Easy change of grippers via QuickChanger with feedback to the production system.

- 100% control of blister input quality and automatic separation of not-OK pieces.

- Stand-alone as well as serial use of the machine - recipe/product type entry can be done either via the local PLC panel or via a higher-level system into which the machine can be integrated.

- At the customer's request, TEMEX can modify the machine in a single-purpose and fast way.