Product laser marking

Product laser marking = precise and high-contrast marking of plastic and metal components

LASER MARKING OF PRODUCTS

TEMEX has been a certified Panasonic system integrator in the field of laser marking for more than 10 years. In our applications, we incorporate state-of-the-art marking lasers, both as part of single-purpose machines and as stand-alone devices to be integrated into larger installations.

Panasonic Authorized Distributor Certificate

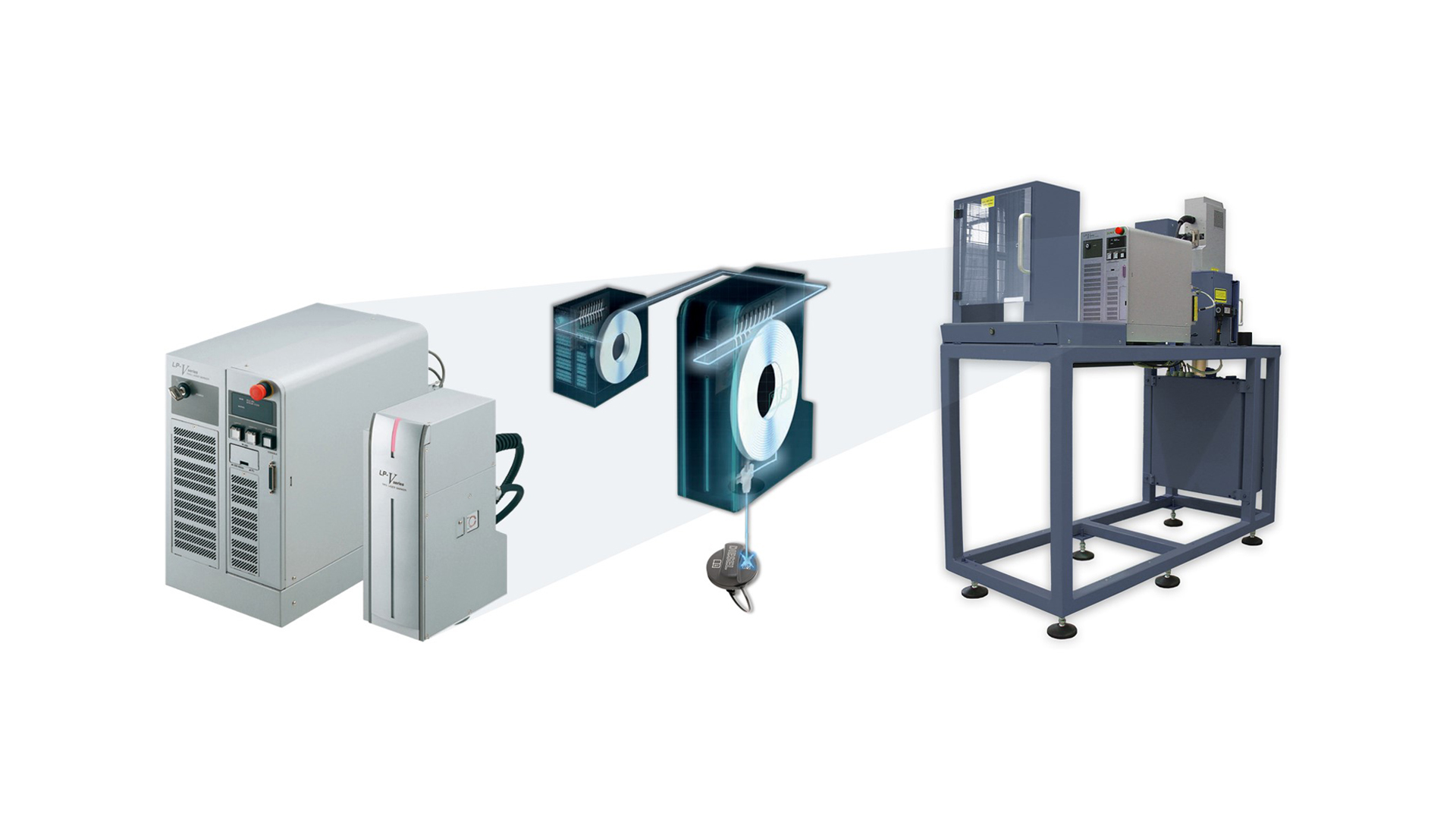

We use a proven fiber laser marking system in our single-purpose machines for marking plastic and metal products. The Panasonic LP-V series is based on advanced technology and offers many advantages over conventional systems. The fiber laser marker has a very low power consumption due to the use of a simple air cooling design. The LP-V can mark in deep black on virtually any type of metal. Plastics are labeled with excellent quality using the technologies of material foaming, carbonization (color change) or bleaching.

LASER MARKING TECHNIQUES FOR METAL PRODUCTS OR CERAMICS

• Engraving – during laser engraving, the workpiece surface is melted and evaporated with the laser. Consequently, the laser beam removes the material. Even very hard metals and ceramics are markable with this technique.

• Annealing – used on metals such as stainless steel and titanium. The heat effect of the laser beam results in microstructural changes and the formation of an oxide layer. Depending on the temperature and thickness of the oxide layer, this method generates different colours.

LASER MARKING TECHNIQUES FOR PLASTIC PRODUCTS

• Karbonizací (pro světlé plasty) – vzniká termochemická reakce na povrchu výrobku (tmavý popis na světlém podkladu), kdy samotný povrch zůstává bez poškození.

• Pěněním (pro tmavé plasty) – vytvořením malých bublinek na povrchu plastu dochází ke světlému popisu na tmavém pozadí. Popis lze i zvýraznit.

• Odstraněním vrstvy (pro vrstvené materiály) – jedná se o selektivní odstranění vrchních vrstev odpařením, kdy hloubku lze ovládat řízením výkonu laseru.

TEMEX LASER MARKING SOLUTION

Fuel tank cap laser marking device

- The whole machine consists of a laser unit LP-V15U-C, a marking chamber, an embedding jig and electrical equipment consisting of a SIEMENS control system and an operator panel.

- The laser unit is linked with the control system and the emergency stop circuit.

- Before the start of production, the operator sets the product description type on the operator panel, which then presets the laser.

- The device includes multiple automatic checks for the presence and correct positioning of the labeled fuel caps.

- A two-hand (ambidextrous) control is used to start the cycle and to ensure safety.

- Products can be encrypted for two-level labeling. In this case, labeling is performed first after insertion under the laser and again after lifting the product to the second level.

Fuel pump motor laser marking device

- The entire control system and the laser unit is switched on by the main power switch. At the same time, the computer, which operates the laser itself and sends labeling data, is automatically switched on.

- The control panel allows the operator to easily change the motor type settings, so laser marking can be applied to several motor types.

- Once the fuel pump motor has been inserted into the loader and the marking device has been started by pressing the "Start" button, the automatic marking mode is initiated.

- Operator safety is ensured during the marking process by closing the marking chamber door and by an electro-mechanical lock, which is released only after the marking cycle is completed.

- After completing the cycle, the operator can replace the described motor with a new one and, if necessary, select another type of description according to the technological procedure of production.

Key benefits of our solution:

- LP-V Laser marking system provides better laser beam quality

- Reduces the size of the housing and the machine itself

- Offers significantly longer lifetime

- Lower fixed costs

- Individual adaptation to the client's requirements