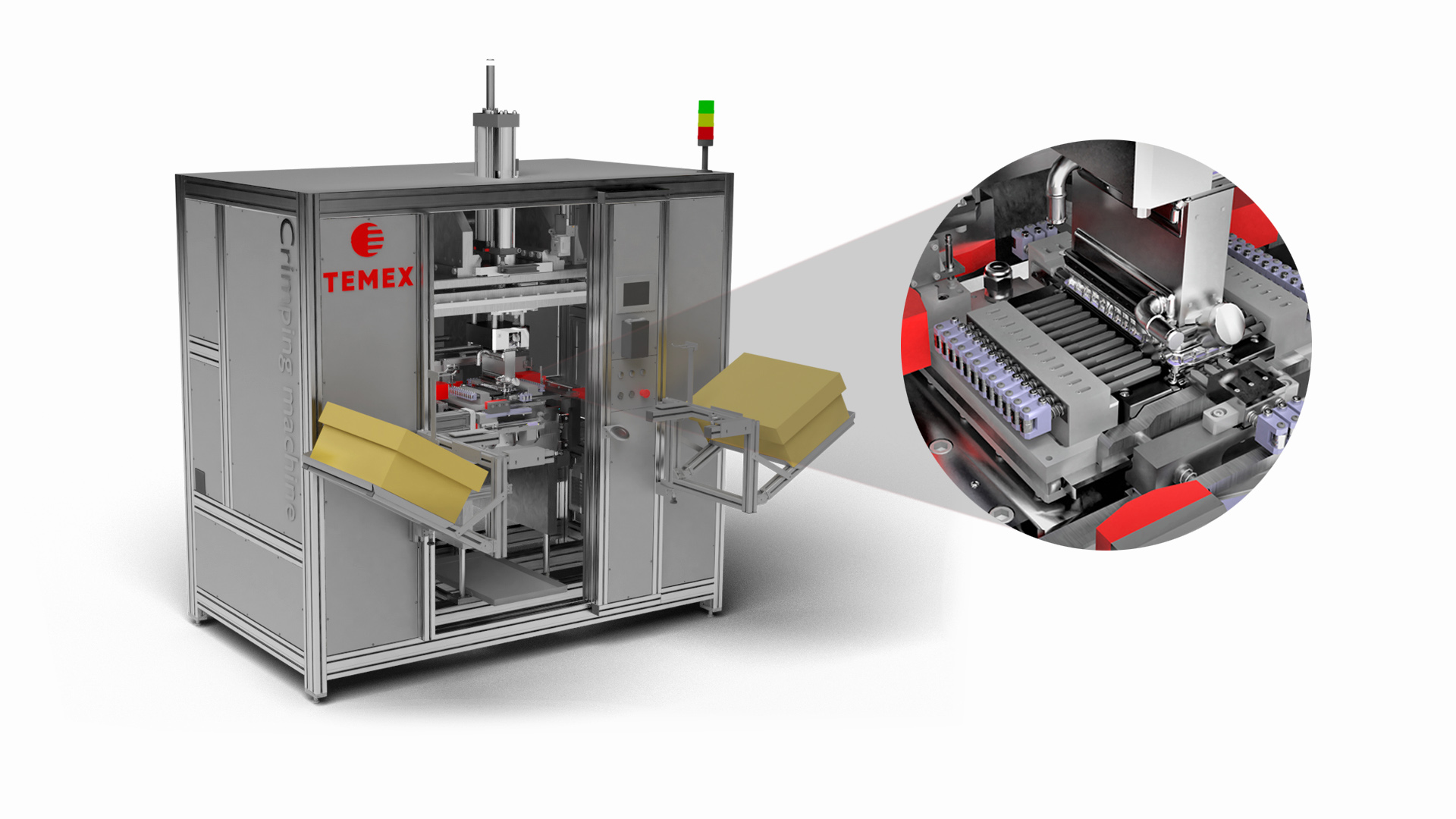

Finger crimping machine for crimping radiators

Radiator crimping = firm connection of the plastic lids to the radiator core

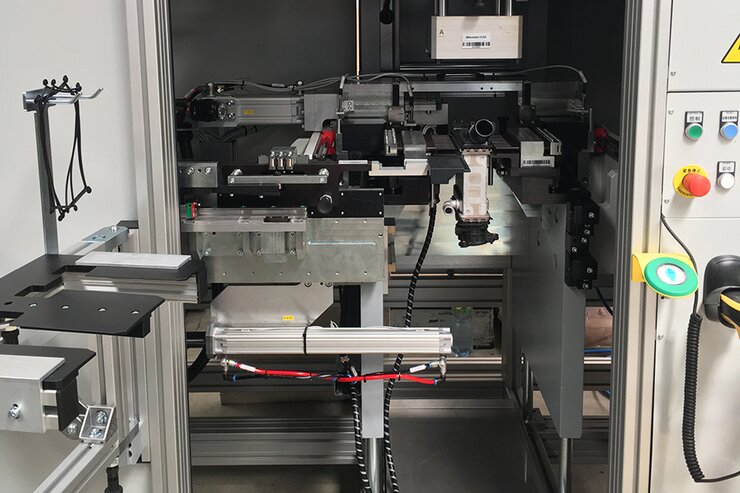

MACHINE FOR CRIMPING RADIATORS – CRIMPING MACHINE

BASIC CHARACTERISTICS

The machine for crimping radiators is used to make a firm connection (crimping) of plastic lids with the radiator core. We have already delivered this machine to countries such as Germany, South Korea, China, Mexico, USA, South Africa, .. The machine is always modified according to customer requirements. With the help of our crimps, coolers of brands such as: VW, AMG, TESLA, BMW, HONDA, VOLVO, etc. are assembled.

- The crimping machine has been designed so that it is possible to crimp different types of radiators of the same concept using interchangeable tools.

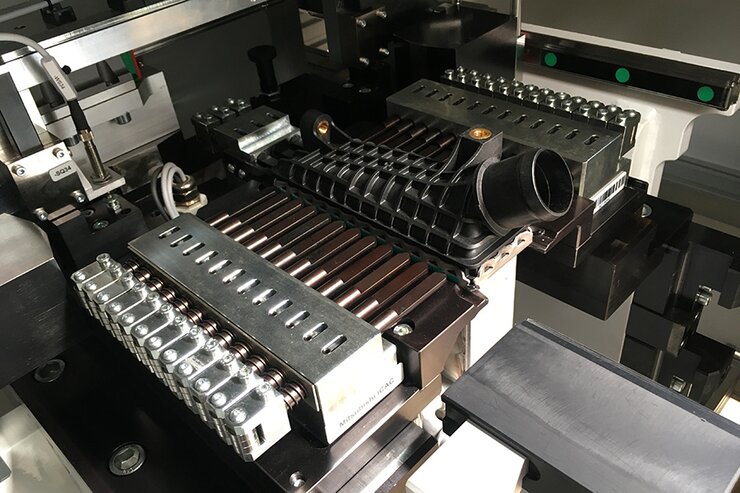

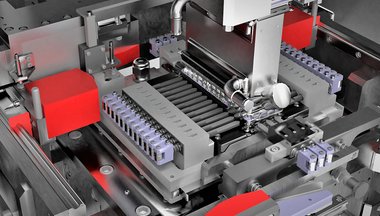

Crimping tool parts:

• Crimping head A

• Crimping head B

• Main lower tool

• Front tool

• Board for assembly workplace (2 pcs)

INPUT MATERIAL

• Gaskets (2 pcs)

• Lid A

• Lid B

• Radiator core

DESCRIPTION

1. The operator attaches a seal and a type A cover to the radiator core in the 1st assembly station.

2. The operator removes the prepared core from the assembly station and inserts it into the crimping machine.

3. The operator presses the green START button.

4. The machine then closes the door and starts the A-side crimping cycle.

5. After successfully crimping side A, the machine moves to side B and the machine door opens.

6. The operator removes the cooler from the machine, rotates it 180 ° and inserts it into the 2nd assembly station.

7. The operator attaches the seal and type B cover to the heat sink core and inserts it back into the machine.

8. The operator presses the green START button.

9. The machine then closes the door and starts the B-side crimping cycle.

10. After successful crimping, the machine door opens and the operator removes the finished cooler.

CONTROL OF THE PRODUCTION PROCESS

- The radiator crimping machine includes various controls to prevent the production of the wrong piece.

- The type and orientation of the inserted lid in the machine is checked using a Keyence camera sensor.

- Depending on the type of tool, the orientation of the radiator core, the color or the presence of the lug is then checked (again with a Keyence camera sensor or Keyence LR-W or LR-Z sensors).