Development and production of machines

WE MANUFACTURE SPECIAL MACHINES AND PRODUCTION LINES

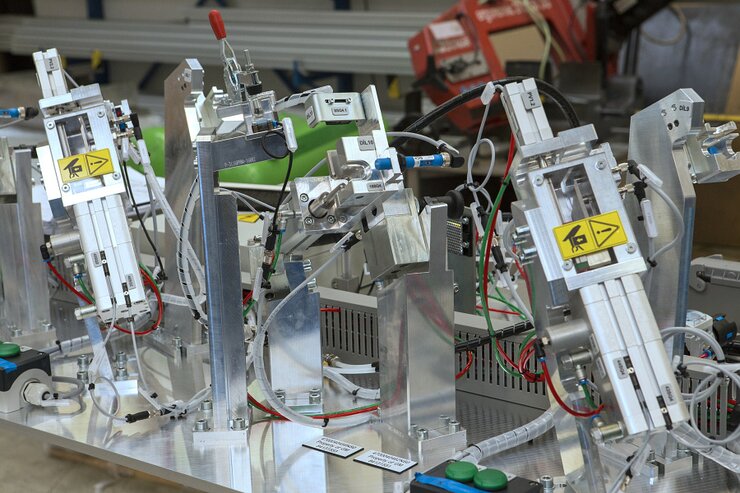

We are engaged in the development, design and production of single-purpose machines and lines for all industries. We provide our many years of know-how to our customers not only in the automotive and electrical engineering industries, but also in the food industry and many other sectors.

Throughout our existence, we have developed and delivered hundreds of machines and lines that you can find on almost every continent. Each device is developed in close cooperation with the end customer in order to achieve the required parameters.

We have an extensive team of experienced developers and designers, whose skills have been used in the implementation of a number of orders in demanding industrial capacities, including the automotive and food industries. We provide everything from the design of the solution, the production, programming, and creation of the technical documentation, all the way to the final installation, operator training and handover to production.

Our machines are used for various production operations, such as assembly, pressing, testing, measuring, shaping, inspection and electrical testing. We also modernize and optimize existing equipment. We work with Siemens S7-200, S7-300 and S7-1200 control systems. We place maximum emphasis on reliability, and contributing to this is the fact that we put exclusively high-quality and proven components in our machines from leading Czech and foreign manufacturers (BALUFF, FESTO, HIWIN, KEYENCE, LENZE, LINTECH, RAVEO, SICK, SIEMENS, SMC).

Our customized machine production can be divided into three groups:

Fully automated – production lines:

- Compact, stand-alone assembly machines and lines, operator-driven or fully automatic.

- Single-purpose machines arranged on the line in a modular way and connected by a system of conveyors for the flow of manufactured production and input materials.

Semi-automatic workstations and modules

- Assembly of products

- Functionality testing

- Cutting, punching, shearing and chopping

- Applications – dosing of adhesives, pasting

- Pressing and riveting

- Welding and soldering

- Describing and marking products

- Sorting of parts, including camera inspections

- Camera control system – aoi

Robotized workplaces

- Product handling

- Assembly of components, sub-assemblies and units

- Palletization at the end of production lines

- Depalletization of input semi-finished products

- Product packaging

- Stackers for machine tools and forming machines

What are we really good at?

- The loading or removing of parts

- Robotic palletizing and depalletizing

- Camera control systems

- Automated workplaces for checking the tightness of liquids and gases

- Lines for assembling parts for the automotive industry