Nutzfahrzeuge lock set assembly machine

SPECIFICATION

The project was implemented at the customer’s request for the design and production of equipment for assembling lock sets.

The project consists of three stations and a conveyor:

1. JÚS – Pre-assembly of the door insert

2. JÚS – Assembly of the door insert

3. JÚS – Pre-assembly of the paddle latch subassembly

4. Conveyor to the Nutzfahrzeuge assembly line

The individual equipment forms part of the assembly line in the production hall in Týniště nad Orlicí.

Solution

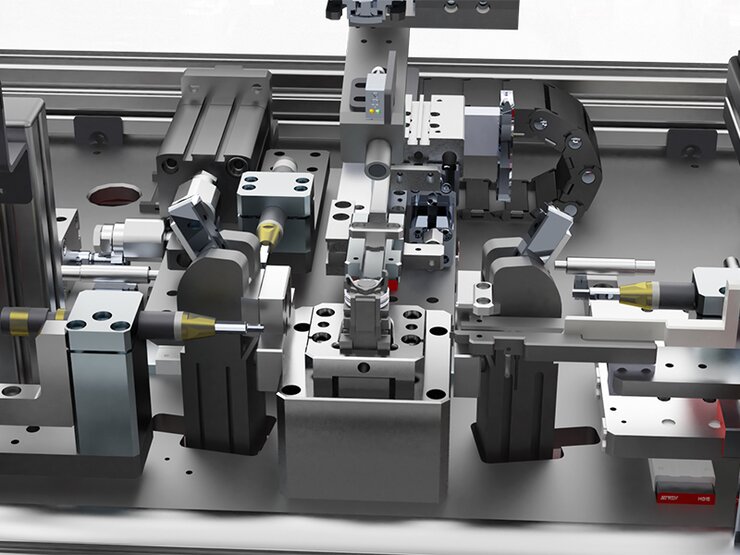

1. JÚS – Pre-assembly of the door insert |

|

|---|---|

| Operation cycle: | 20 seconds |

| Capacity: | 250,000 pieces per year |

Description

1.1. The machine is designed as a semi-automated workplace for one operator. The inserted parts are checked by sensors for their presence and correct placement.

1.2. The operator inserts the body with the drum into the lubricant and lubricates it with a dose of lubricant. The operator places the other components on the body with the drum. The assembly is put into the jig and the parallel keys are placed in front of the mounting pins. After pressing the START button, the work area is closed off by means of a safety door with a touch safety bar. The automatic cycle then begins - the body is gripped with clamps and the mounting mechanism descends from above and mounts the spring to the body. The parallel keys are mounted in the body and the edges sealed. Next follows the detection of mounted components. The piece is unclamped, the automatic door slides up and then the operator removes the piece and continues with it for the next operation. The cycle keeps repeating itself.

2. JÚS – Assembly of the door insert |

|

|---|---|

| Operation cycle: | 20 seconds |

| Capacity: | 250,000 pieces per year |

Description

2.1. The machine is designed as a semi-automated workplace for one operator. The inserted parts are checked by sensors for their presence and correct placement.

2.2. The operator places the assembly on the lubrication mandrel, inserts the paddle assembly into the upper jig, which is securely clamped to the pneumatic cylinder in the jig. Once placed, the components are detected by sensors. The operator leaves the work area. After pressing the START button, the automated cycle begins - the body is clamped, lubricated with a dose of lubricant through the lubrication mandrel, a guide spring with lubrication nozzle appears from behind and the paddle assembly mounting mechanism descends from above to mount the paddle into the body and tests the correct orientation and function of the ring by pulling. The spring is lubricated from the back. Everything returns to their basic position and the assembly is unclamped and the operator can remove the piece and continue with it for the next operation. The cycle keeps repeating itself.

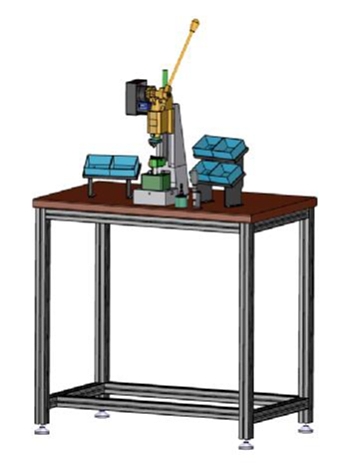

3. JÚS – Pre-assembly of the paddle latch subassembly |

|

|---|---|

| Operation cycle: | 15 seconds |

| Capacity: | 250,000 pieces per year |

Description

3.1. The machine is designed as a manual workplace for one operator. It consists of the customer-supplied table, a mechanical hand press with reciprocating movement restriction and an adapted loading bed. The inserted parts are checked by the operator.

3.2. The operator loads all components into the loading bed of the hand press. The correct orientation is the responsibility of the equipment operator. The operator performs the assembly by moving the press lever to the maximum dead center – all components are pressed into the housing. The operator next places the subassembly onto the loading bed for fitting the spring and uses an aid to attach the return spring to the housing.

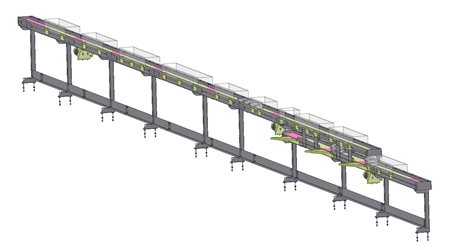

4. Conveyor to the Nutzfahrzeuge assembly line |

|

|---|---|

| Operation cycle: | 40 seconds |

| Capacity: | 250,000 pieces per year |

Description

4.1. The roller conveyor with chain drive is used to transport the pallets with production material. Individual workplaces can be switched on and off. When the workplace is switched off, the pallets pass through the idle zone to other workplaces.

Key benefits of our solution

- Minimizes scrap

- Manpower savings

- Eliminates work-related injuries during handling

- Production and downtime statistics

JÚS - Pre-assembly of the paddle subassembly

Conveyor to the assembly line

Conveyor workplace