100 kJ drop-weight impact machine

TEST EQUIPMENT FOR PERFORMING THE CHARPY IMPACT TEST DWTT

Name of contract: 100 kJ drop-weight machine

Term of delivery: 2016

SPECIFICATION

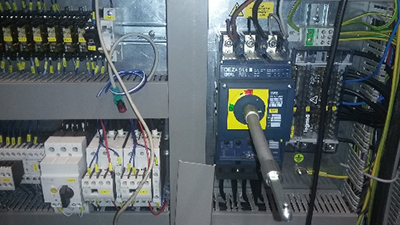

Complete delivery of electrical parts of the machine, including SW and startup.

DESCRIPTION

The machine works on the principle of lifting and dropping a ram onto a test specimen, and the data from this test is analyzed to determine the quality of the material’s strength. The structure of the entire machine is made up of a steel frame, the upper part of which contains the drive unit for the ELHA lifting equipment clamp used to grip the ram.

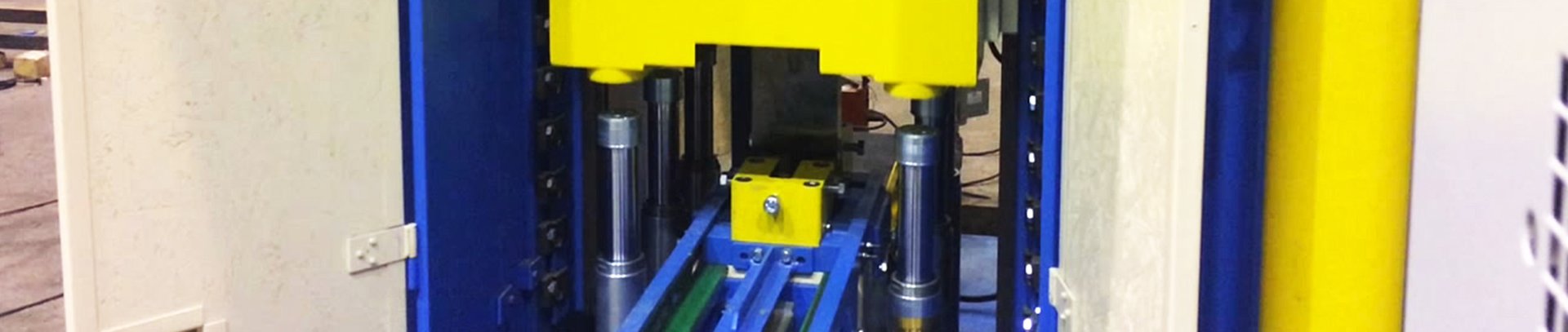

The lower part of the machine contains the drop area with a clamping fixture to grip the tested specimen of the material. Put simply, it is about the principle of lifting a drop-weight load and releasing it to fall and impact a test specimen of steel, held into place in the drop area by the clamping fixture.

The lower part of the drop area is equipped with a door with safety locks attuned to the position of the barrier and ram. The switches for the door interlock open the locks when the ram is in the position above the safety barrier or in the lower position for repairs or maintenance, as well as for changing the weight.

The loading of test specimens is done by means of a manipulator, where the input loading opening has a cover with a disabling switch. After the test the specimens are transported by conveyor without the need of manual operation.

Installed above the drop chamber is a barrier to prevent the ram from entering the drop area of the chamber and a place to park the ram when not in use.

Two systems are used to suspend the ram:

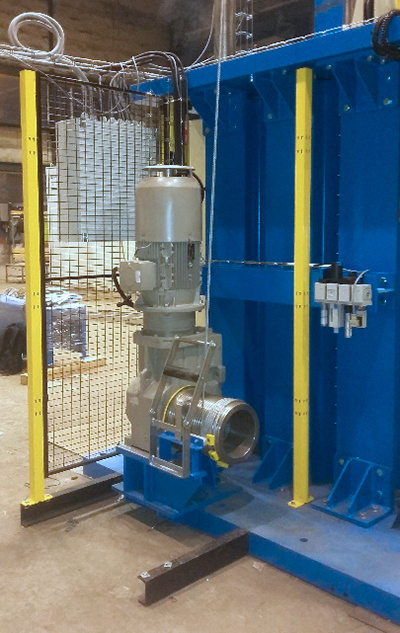

- The electromagnetic system is used to suspend the ram and put it aside.

- An electro-hydraulic thruster (ELHA) detects the position of the clamping fixture and presence of the hoisted ram and serves as a safety device against unintended drops, for example in the event of a loss of electricity

- The hoist is fixed via a pulley to a steel rope with adequate strength.

- The upper end of the ram’s position is sensed by an operating sensor and a safety position sensor.

- After meeting the conditions for lifting and dropping the ram – i.e. the tested specimen is in the clamping fixture, the door to the drop chamber is closed and secured and the safety barrier above the chamber is extended – the ELHA clamps are opened and the weights are released by switching off the current to the electromagnet.

- Performing the test or starting the machine is controlled from the control panel. The readiness of the equipment for the test is signaled by an audible and visual signal.

- After the test, the specimen is hauled away by a conveyor to the operator’s station and another test may follow if necessary.